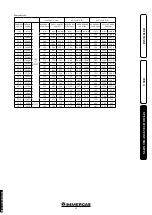

28

3-3

4

3

2

1

5

6

INS

TALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

Key:

1 - Coil

2 - Minimum power adjustment screw

3 - Maximum power adjustment nut

4 - Gas valve outlet pressure point

5 - Gas valve inlet pressure point

6 - Protection hood

SIT 845 GAS Valve

3.7 CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

After making sure that conversion was carried

out with a nozzle of suitable diameter for the

type of gas used and the settings are made at the

correct pressure, check that:

- there is no flame in the combustion chamber

- the burner flame is not too high or low and that

it is stable (does not detach from burner)

- the pressure testers used for calibration are

perfectly closed and there are no leaks from

the gas circuit.

N.B.:

all boiler adjustment operations must be

carried out by a qualified company (e.g. Author-

ised After-Sales Assistance). Burner adjustment

must be carried out using a differential "U" or

digital type pressure gauge connected to the

pressure socket located above the sealed cham-

ber (part. 9 Fig. 1-29) and the gas valve pressure

outlet (part. 4 Fig. 3-3), keeping to the pressure

value given in the table (Par. 3.18) according to

the type of gas for which the boiler is prepared.

3.8 POSSIBLE ADJUSTMENTS.

N.B.:

to adjust the gas valve, remove the plastic

cap (6); after adjusting, refit the cap.

• Preliminary calibration operations.

- Set parameter S0 at 0 %.

- Set parameter S1 at 99 %.

• Activate the chimney sweep function.

- Enter the “DHW chimney sweep” mode,

opening a DHW cock.

• Adjustment of boiler nominal thermal heat

output.

- Set the power at maximum (99%) by turning

the “CH regulator” selector (1).

- With the brass nut (3 Fig. 3-3) adjust the

boiler nominal output, observing the maxi-

mum pressure values stated in the tables (Par.

3.18) according to the type of gas; by turning

clockwise the heat potential increases, anti-

clockwise it decreases.

• Adjustment of boiler minimum thermal heat

output.

N.B.:

only proceed after having calibrated the

nominal pressure.

- Set the power at minimum (0%) still using

the “CH regulator” selector (1).

- Adjust the minimum thermal input by op-

erating on the cross plastic screws (2) on the

gas valve maintaining the brass nut blocked

(3);

• Exit the “Chimney sweep” mode and keep the

boiler functioning.

• Adjustment of the boiler minimum heat output

in heating phase.

N.B.:

only proceed after having calibrated the

minimum boiler pressure.

- To adjust the minimum heat output during

the heating phase, change parameter (S0),

increasing the value the pressure increases,

reducing it the pressure drops.

- The pressure to which the boiler minimum

heat output must be adjusted, must not be

lower than that stated in the tables (par. 3.18).

• Adjustment (any) of the boiler maximum heat

output in central heating phase.

To adjust the maximum heat output during

the heating phase, change parameter (S1),

increasing the value the pressure increases,

reducing it the pressure drops.

- The pressure to which the boiler maximum

heat output must be adjusted in central heat-

ing phase, must not be carried out in refer-

ence to that stated in the tables (Par. 3.18).

3.9 SLOW AUTOMATIC IGNITION

FUNCTION.

In ignition phase, the P.C.B. supplies constant

gas with pressure proportional to the parameter

"S4" set.

3.6 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a different

gas type to that specified on the data nameplate,

request the relative conversion kit for quick and

easy conversion.

The gas conversion operation must be carried

out by an authorised company (e.g. Authorised

Technical After-Sales Service).

To convert to another type of gas the following

operations are required:

- disconnect the appliance;

- replace the main burner injectors, making sure

to insert the special seal rings supplied in the

kit, between the gas manifold and the injectors;

- re-power the appliance;

- from the push button panel on the boiler, select

the type of gas (S2) and then select (

Ng

) if it

runs on Methane or (

Lg

) if it runs on LPG;

- adjust the boiler nominal heat output;

- adjust the minimum heat power of the boiler;

- adjust the boiler nominal heat output in heating

phase;

- adjust (eventually) the maximum heating

power;

- seal the gas flow rate regulation devices (if set-

tings are modified);

- after completing the conversion, apply the

sticker, contained in the conversion kit, near

the data nameplate. Using an indelible marker

pen, delete the data relative to the old type of

gas.

These adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.18).

STD.002998/004

Summary of Contents for MAIOR EOLO 24

Page 1: ...MAIOR EOLO 24 28 32 Instruction and recommendation booklet 1 038763ENG STD 002998 004 ...

Page 2: ...STD 002998 004 ...

Page 31: ...31 3 5 6 6 7 8 8 f f e INSTALLER USER MAINTENANCE TECHNICIAN STD 002998 004 ...

Page 37: ...37 STD 002998 004 ...

Page 38: ...38 STD 002998 004 ...

Page 39: ...39 STD 002998 004 ...