Technical documentation

Technical documentation

STEM@ ed 06/01

14

EOLO MAIOR @

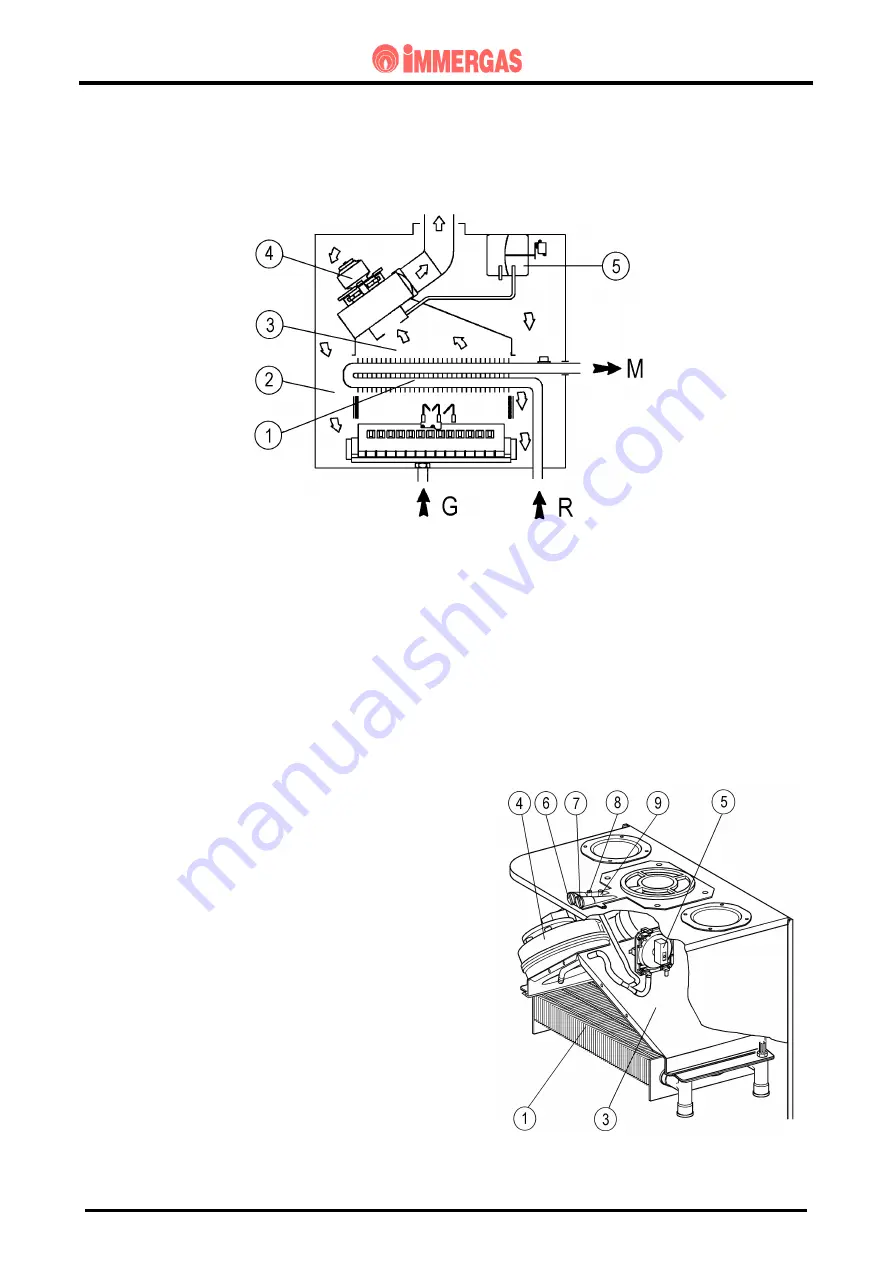

FLUE CIRCUIT

- OPERATION

The combustion residues, after investing the water-gas exchanger (1), are conveyed to a hood (3) at the

top of which is a draught diverter (4).

Operation of the fan ensures forced extraction of the flues and at the same time creates a vacuum in the

sealed chamber (2) that permits extraction of the combustion air from outside.

Correct flue extraction is controlled by a differential pressure switch (5), operation of which enables or

does not enable burner ignition.

- AIR/FLUE SAMPLING SUMPS (6-7)

The top outer part of the chamber features two

sumps with screw closing accessible from the front

and through which combustion air (6) and flues (7)

can be extracted.

- FLUE PRESSURE SWITCH SIGNAL

PRESSURE POINT (8-9)

The top outer part of the sealed chamber features

two pressure points with screw closing for

measuring the signal at the ends of the flue pressure

switch (5).

The negative pressure point (8) is linked through a

Y-pipe to the top of the draught diverter and to the

negative pressure point of the flue pressure switch.

The positive pressure point (9) is directly linked to

the inside of the sealed chamber.