C A L I B R A T I O N A N D T R O U B L E S H O O T I N G

Calibration Overview

7/01

LDC-3700 Series

125

C H A P T E R

5

stabilize.

When the measured value (display) is stable and the Controller is ready to proceed, enter

the value by issuing the "TEC:V <nrf value>" command, where the actual TEC voltage on

the DMM is the <nrf value>. Once the actual TEC voltage value is entered via the

"TEC:V<nrf value>" command, the new calibration value is stored into non−volatile

memory.

Note:

To ensure measurement stability of the actual TEC voltage value when the

measurement is taken as a part of an automated test, the DMM measurement should be

polled in a loop. When the measured value is consistent within one digit for 5 seconds (for

example), the actual TEC voltage value could be considered stable.

If the "*OPC?" query is issued during TEC voltage calibration, the time out period of the

GPIB driver should be at least one minute to prevent the GPIB driver from timing out and

"hanging" the system. Refer to your GPIB driver instruction manual for information on

setting the GPIB driver time out period.

5

The controller will drive the output current to a value of about 0.12 Amps, so that the TEC

voltage will be about +6.00 volts.

6

Repeat step 4. After the value for the positive polarity of the TEC voltage is entered, the

Controller will automatically store the new calibration values for TEC voltage

measurement.

Current Source Calibration

There are three calibration adjustments required for the LASER current source of the LDC−3700B

Series Laser Diode Controller. They are calibration of the constant current source for both

bandwidths and ranges, calibration of the laser voltage measurement, and calibration of the

constant light power (I

PD

) feedback circuits.

The LDC−3700B Series Laser Diode Controller implements a two−point calibration for the Laser

current source. Two currents (approximately 20% and 80% of FS) are applied to a test load, and the

resulting actual currents are fed back (by the user) to the Controller. The Laser Controller calibration

program uses the two sets of data to calculate new calibration constants. These calibration

constants are used to set the actual current of the current source.

The following procedure is for calibrating each range of the current source. Start with the low range.

After calibration is complete in this range, switch to the high range and repeat the procedure.

Configure the Controller in the following manner for the Laser Controller calibration:

1

Measure and record the resistance of a 1

Ω

, 20 W resistor (a 4−point probe resistance

measurement is recommended). Connect the load resistor across the LASER output

terminals (Laser Anode and Laser Cathode) on the 9 pin connector of the rear panel.

2

Connect the calibrated DMM across the load resistor. Configure the multimeter to

measure voltage in volts. You will be calculating the actual Laser current in the following

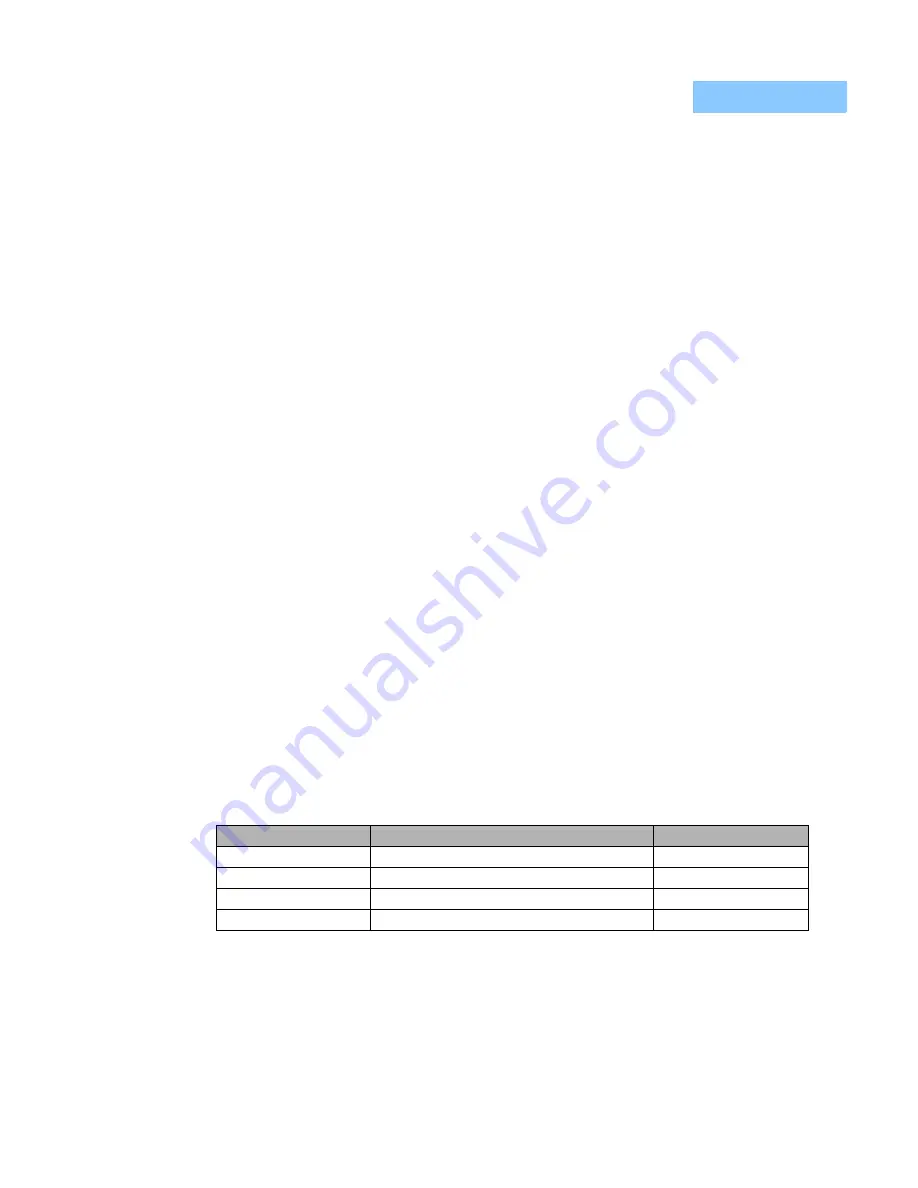

FUNCTION

STATE

GPIB COMMAND

LASER MODE

I (constant current low bandwidth)

LAS:MODE:ILBW

RANGE

low (lowest per instrument model)

LAS:RAN−x

LIMIT

90% of FS (full scale of range)

LAS:LIM:Ix

SET POINT

80% of FS (90% for LDC−3744B)

LAS:LDI

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com