15

UK

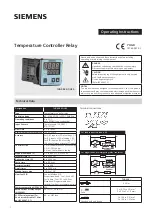

6.5 Outputs

6.5.1 Relay output

► Connect the changeover contact depending on the used valve or pump (→ 6.6

Connection of the valve or pump)�

► To prevent excessive wear and to comply with the EMC standards, interference

suppression of the contacts is required for switching inductive loads�

WARNING

If the device is operated on an AC supply (terminals 21/22 and 23/24) this

must use the same supply cable (phase) as the voltage supply to switch an AC

voltage via the relay output�

If the relay output is used to switch very small currents (e�g� PLC input),

considerable contact resistance can arise� For this purpose use the

transistor output�

6.5.2 Transistor output

► The transistor output needs an ex24 V DC supply on terminal 13�

Protect this +24 V DC supply cable externally with a 315 mA time-lag fuse (5 x

20 mm or similar)�

► Connect the reference point (GND) of the external power supply with terminal

15 or 3/4 of the device� Otherwise no switching operation is possible�

► The SELV criteria (safety extra-low voltage) must be met for the DC supply of

the transistor outputs�

6.6 Connection of the valve or pump

► The principle of normally open operation must be adhered to for the connection

of the valve or the pump� For example, connect the normally open output of the

device (terminals 17/18) to a valve with normally closed operation�

By adhering to the principle of normally open operation the inlet or outlet of

the medium is blocked in the event of a wire break or a power failure�