Page 14 of 68

VL-HP

Service

& Operation Manual

U.S. TAX STAMPING

EQUIPMENT

Manufactured by United Silicone

an ITW company

3.2 Air

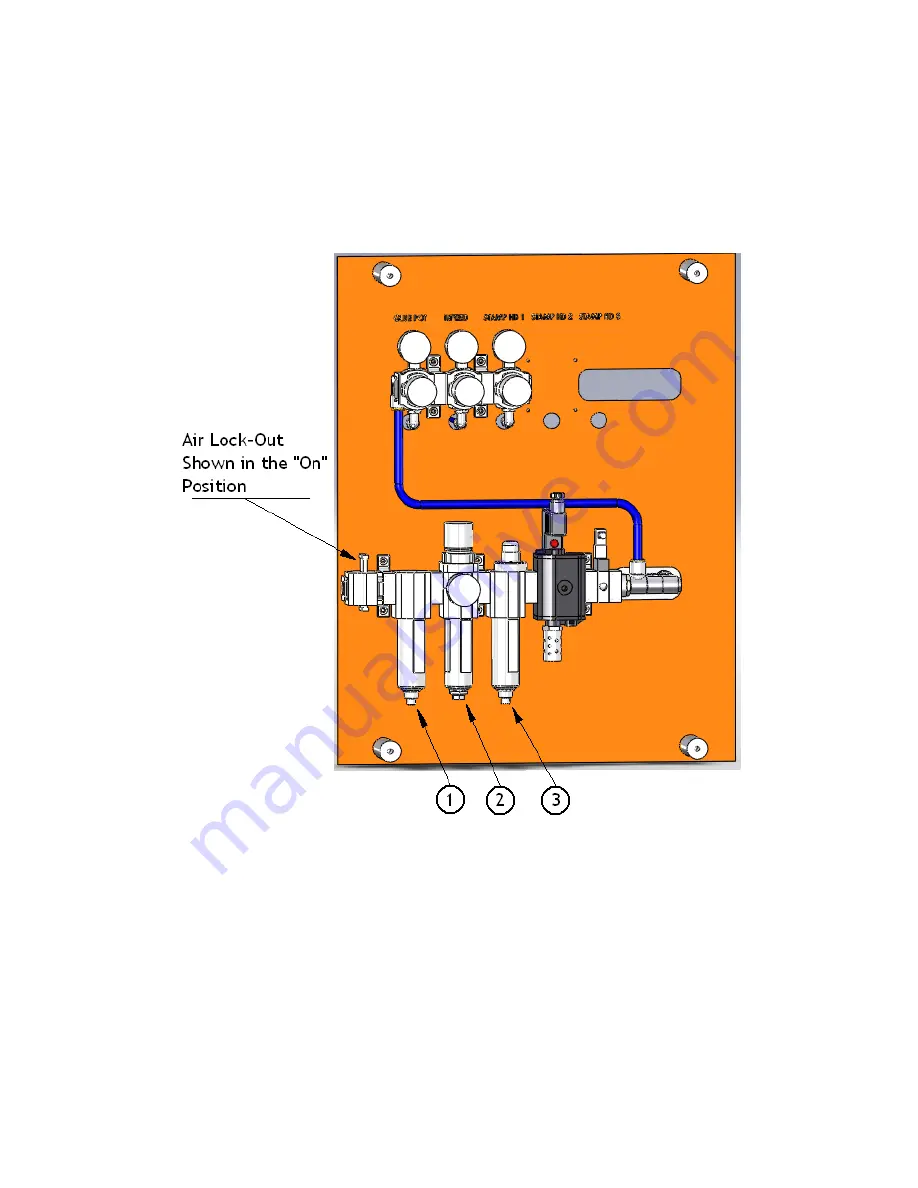

An air control valve is located on the pneumatic panel located on the back of the stamp machine,

near the electrical panel. For the stamp machine to operate, the air lockout must be pushed

upwards to the correct position. This valve is “Lock-Out, Tag-Out” compliant and a lock can be

applied with the valve in the “Off” position.

Figure 3.2 Air inlet panel

Prior to turning on the supply of compressed air to the stamping machine, it is important to check

for the presence of water in the water separator bowl (1), the filter bowl (2), and the coalescing

bowl (3). The VL-HP requires that the compressed air supplied to this stamping machine be

clean and dry. All air coming from an air compressor is “wet” as a result of being compressed

by the compressor. After the air compressor, the compressed air must be dried by passing

through an aftercooler and/or air dryer.

Types and advantages of different compressed air dryers

and other important information about air compressors are contained in Appendix A of this

manual “Supplying Compressed Air to your US Tax Stamping Equipment”.

Summary of Contents for VL-HP

Page 2: ......