10

Z-Series Coro-Vane

®

Seal Replacement Instructions

Step 5

Seal retainer and carbon installation

Clean the pump and apply a generous amount of light oil.

Install the new seal assembly by aligning the seal retainer

slot with the seal drive pin on the shaft.

Step 6

Mechanical seal installation

Install the new case O-ring onto the head.

Apply a generous amount of light oil to each seal face and

carefully install the head assembly over the pump shaft.

Step 7

Completing installation

Torque the head bolts in a crossing pattern. There is no

need to disassemble or re-shim the bearing caps. Repeat

all of the above steps when replacing the seal assembly on

the opposite side.

Step 8

Lubrication & re-pressurizing

Note: Both sides of the pump are identical; duplicate

procedure to change the seal on the opposite side.

Lubrication

Regrease the bearing after thoroughly cleaning the grease

opening and fittings. If dirt is forced into the bearings, early

failure will result.

Special relief fittings have been provided to help prevent

over-greasing the bearings. Excessive grease may drip out

after lubrication. Over-greasing can damage the pump

bearings and cause seal leaks.

Use only a recommended ball bearing grease. If you use a

hand grease gun, put the grease in slowly and stop as soon

as the relief fitting opens.

Grease the U-joints and the spline of the drive shaft when

greasing the pump.

Re-pressurize

For best results, slowly pressurize with vapor pressure.

Please note: If you pressurize with liquid, it will sometimes

refrigerate even though it enters the pump slowly. As a

result, the seal elastomers will not seal properly thereby

causing them to leak.

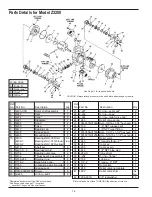

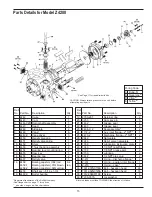

Summary of Contents for Corken Z-Series

Page 31: ......