10

icos system condensing -

Installation and Servicing

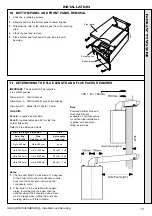

GENERAL

The boiler does not normally need a bypass but at least

some radiators on the heating circuit, of load of at least 10%

of the minimum boiler output must be provided with twin

lockshield valves so that this minimum heating load is

always available. See note regarding thermostatic radiator on

pages 8.

Note.

Systems incorporating zone valves which could completely

cut off the flow through the system, must be wired such that

the boiler will not fire or continue to fire when this occurs.

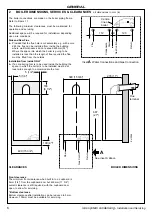

5

SYSTEM BALANCING

BALANCING

1.

Set the programmer to ON.

Close the manual or thermostatic valves on all

radiators, leaving the twin lockshield valves (on the

radiators referred to above) in the OPEN position.

Turn up the room thermostat and adjust these

lockshield valves to give boiler flow and return

temperatures not more than 20

o

C apart.

These valves should now be left as set.

2.

Open all manual or thermostatic radiator valves and

adjust the lockshield valves on the remaining

radiators, to give around 11

o

C temperature drop at

each radiator.

3.

Adjust the room thermostat and programmer to

NORMAL settings.

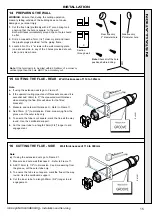

6

WATER TREATMENT

The icos boiler has an ALUMINIUM alloy heat exchanger

IMPORTANT.

The application of any other treatment to this product may render the guarantee of Caradon Plumbing invalid.

If water treatment is used

Caradon Ideal Limited

recommend only the use of

FERNOX-COPAL or SENTINEL X100

water

treatment products, which must be used in accordance with the manufacturers' instructions. For further information contact:

Fernox Manufacturing Co. Ltd.

Sentinel Division

Betz Dearborn Ltd., Widnes, Cheshire, WA8 8UD

Tel: 0151 424 5351

Tandem House, Marlowe Way, Croydon, Surrey, CRO

4XS

Tel: 0870 5601 5000

Notes

.

1.

It is most important that the correct concentration of the

water treatment product is maintained in accordance with

the manufacturers' instructions.

2.

If the boiler is installed in an existing system any

unsuitable additives

MUST

be removed by thorough

cleansing.

BS. 7593:1992 details the steps necessary to clean a

domestic central heating system.

3.

In hard water areas, treatment to prevent lime scale

may be necessary - however, the use of artificially

softened water is

NOT

permitted.

4.

Under no circumstances should the boiler be fired

before the system has been thoroughly flushed.

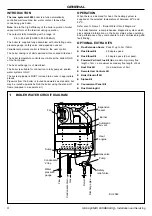

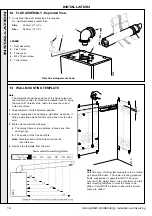

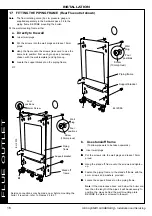

13.

Heat engine.

14.

Injector assembly.

15.

Venturi assembly.

16.

Fan assembly.

17.

Automatic air vent.

18.

Gas service cock.

19.

Gas valve.

20.

Fan bracket.

21.

Orifice plate.

22.

Dry fire thermostat.

23.

Control thermistor.

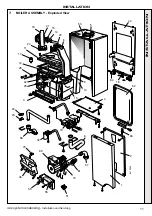

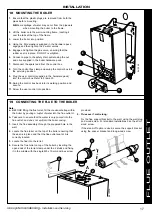

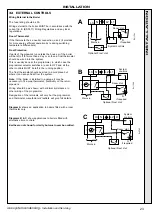

1.

Front panel.

2.

Boiler sealing panel.

3.

Sump cover.

4.

Bottom panel.

5.

Flue sensing nipple.

6.

Return pipe.

8.

Flue manifold.

9.

Flue manifold fixing.

10.

Interpanel.

11.

Burner.

12.

Comb. Chamb. insulation.

7

BOILER ASSEMBLY - Exploded View Legend

24.

Overheat thermostat.

25.

Ignition electrode.

26.

Flame sensing electrode.

32.

Condensate 's' trap.

35.

User control.

36.

Primary controls (PCB).

39.

Mains switch.

42.

Sightglass.

44.

Piping frame.

51.

Mains connector.

53.

Turret seal.

57.

CH return stub.

58.

CH flow stub.

61.

Pressure relief valve.

62.

Expansion vessel.

63.

Exp. vessel pipe assy.

64.

Pressure gauge.

69.

Pump.

70.

Pump manifold.

75.

Control box clamp

Summary of Contents for icos system m3080

Page 1: ......

Page 51: ...51 icos system condensing Installation and Servicing NOTES ...

Page 53: ......