24

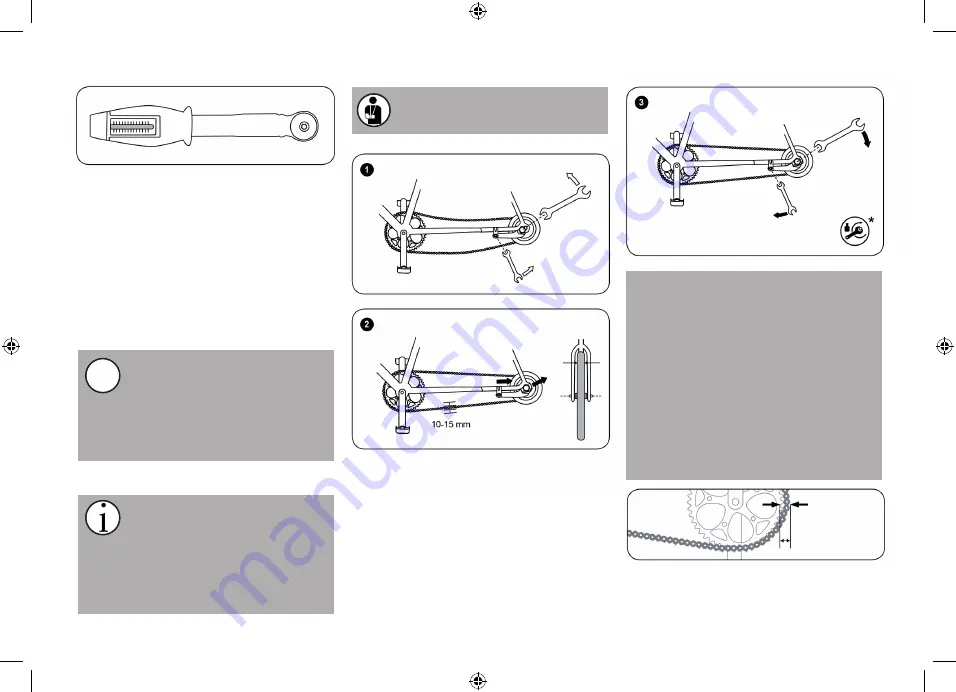

Torque spanners

Chain

To ensure that it can work effectively, the chain

has to be cleaned and greased regularly (see

page 36). Dirt can be removed when washing the

rest of the bicycle. Otherwise you can clean the

chain by rubbing it with an oily cloth. When the

chain is clean, it should be greased at the joints

with suitable lubricant. After being left to soak,

the excess lubricant should then be removed.

To ensure that the chain and gears

can work safely, the chain has to have

a certain level of tension. Derailleur

gear systems tense the chain automatically.

In the case of hub gears, chains which are too

loose have to be tightened. Otherwise they

can come off and lead to a fall.

Chain tension

In the case of bicycles with adjustable

dropouts, the mounting screws of the

axle housing should be loosened and

tightened, and not the axle nuts. If the bottom

bracket shell contains an eccentric bush,

please tighten the chain according to the

instructions provided by the corresponding

manufacturer.

Please ensure that axle nuts and

boosters are correctly attached!

Dirt and permanent strain wear the chain. The

chain should be replaced as soon as it can

be significantly lifted (approx. 5 mm) from

the front chain ring. Many modern chains for

derailleur gear systems no longer have chain

connectors. You therefore require specialist

tools to open/change/close them. This work

should be carried out by a specialist retailer.

Other chains are supplied/assembled with

chain connectors. In some cases, these can

be opened without the need for tools. These

chain connectors can also be used to repair

a damaged chain on a ride, if they have the

correct width for the drive train.

* see page 37

!

IDEAL MANUAL 2016_eng.indd 24

6/27/16 11:39