16

Table 3

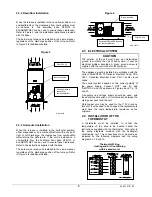

Air Flow - CFM (Units with 1/2 HP, 4 speed motors)

Table 4

Minimum clearances from combustible material

0.2" (W.C.)

0.3" (W.C.)

0.4" (W.C.)

0.5" (W.C.)

0.6" (W.C.)

0.7" (W.C.)

HIGH

1550

1510

1460

1400

1320

1220

MED-HIGH

1320

1280

1240

1200

1160

1020

MED-LOW

1180

1150

1110

1080

1040

940

LOW

1070

1040

1010

980

910

840

BLOWER

SPEED

EXTERNAL STATIC PRESSURE WITH AIR FILTER

UPFLOW

HORIZONTAL

DOWNFLOW

FURNACE

1

2.54 cm (1")

N/A

5.08 cm (2" )

PLENUM AND WARM-AIR DUCT WITHIN 6 ft. OF FURNACE

1

5.08 cm (2")

2.54 cm (1")

5.08 cm (2" )

BOTTOM

FURNACE

2

Ø

2.54 cm (1")

3

5.08 cm (2")

4

BACK

FURNACE (OPPOSITE SIDE OF THE B URNER)

1

7.62 cm (3")

7.62 cm (3")

7.62 cm (3" )

PLENUM OR HORIZONTAL WARM-AIR DUCT WITHIN 6 ft. OF FURNACE

2

5.08 cm (2")

7.62 cm (3")

5.08 cm (2" )

FURNACE

2

N/A

5.08 cm (2")

N/A

FLUE PIPE

AROUND FLUE PIPE

22.86 cm (9" )

22.86 cm (9")

22.86 cm (9")

FRONT

FURNACE (BURNER S IDE)

1

45.72 cm (18")

45.72 cm (18")

45.72 cm (18")

1

These are horizontal dimensions

2

These are vertical dimen sions

3

This dimensi on can be obtained by using Horizontal Flow Base # HFB-101 or # K LASB0701DET

4

This dimension can be obtained by using Downflow Base # DFB-103 or # K LASB0901DET

LOCATIO N

SIDES

TOP

445 01 4101 00

Summary of Contents for OMF112K14A

Page 17: ...17 Figure 5 Furnace dimensions 445 01 4101 00...

Page 18: ...18 Figure 6 Wiring Diagram 4 Speed Motor PSC 445 01 4101 00...

Page 19: ...19 Figure 7 Wiring Diagram Variable Speed Motor ECM 445 01 4101 00...

Page 20: ...20 PARTS LIST With 4 Speed motor PSC B50091B 445 01 4101 00...

Page 22: ...22 PARTS LIST With variable speed motor ECM B50092B 445 01 4101 00...