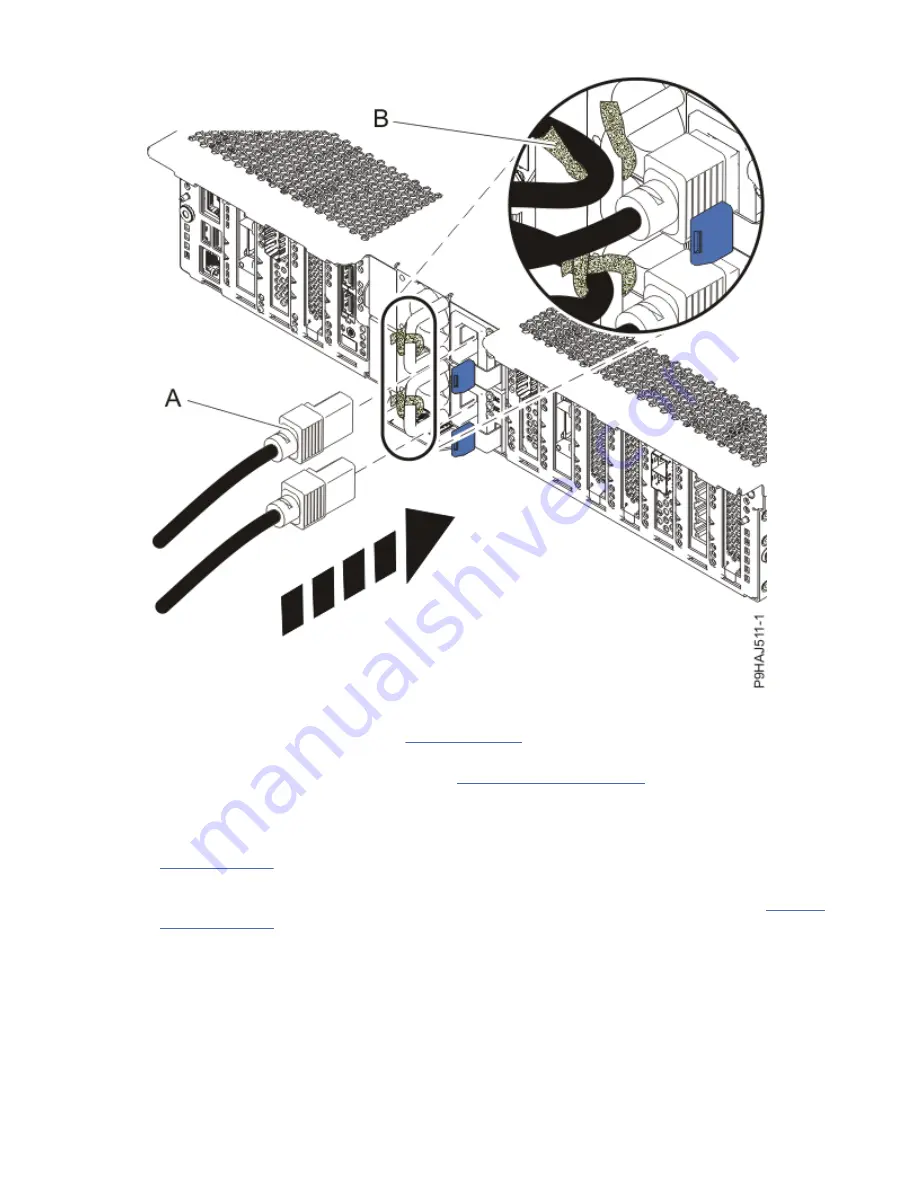

Figure 69. Connecting the power cords

5. Start the system. For instructions, see Starting a system (www.ibm.com/support/knowledgecenter/

POWER9/p9haj/crustartsys.htm).

6. Turn off the identify LED. For instructions, see Deactivating an identify LED (www.ibm.com/support/

knowledgecenter/POWER9/p9haj/p9haj_turn_off_identify_led.htm).

7. Verify the installed part.

• If you replaced the part because of a service action, verify the installed part. For instructions, see

Verifying a repair (www.ibm.com/support/knowledgecenter/POWER9/p9ect/

pxect_verifyrepair.htm).

• If you installed the part for any other reason, verify the installed part. For instructions, see Verifying

the installed part (www.ibm.com/support/knowledgecenter/POWER9/p9haj/pxhaj_hsmverify.htm).

78 Power Systems: Power Systems: Drive backplane

Summary of Contents for 9009-22A

Page 4: ...iv...

Page 14: ...xiv Power Systems Power Systems Drive backplane...

Page 16: ...Figure 1 Removing the power cords L003 or or 2 Power Systems Power Systems Drive backplane...

Page 80: ...66 Power Systems Power Systems Drive backplane...

Page 82: ...Figure 61 Removing the power cords L003 or or 68 Power Systems Power Systems Drive backplane...

Page 94: ...Figure 70 Removing the power cords L003 or or 80 Power Systems Power Systems Drive backplane...

Page 115: ......

Page 116: ...IBM...