3.

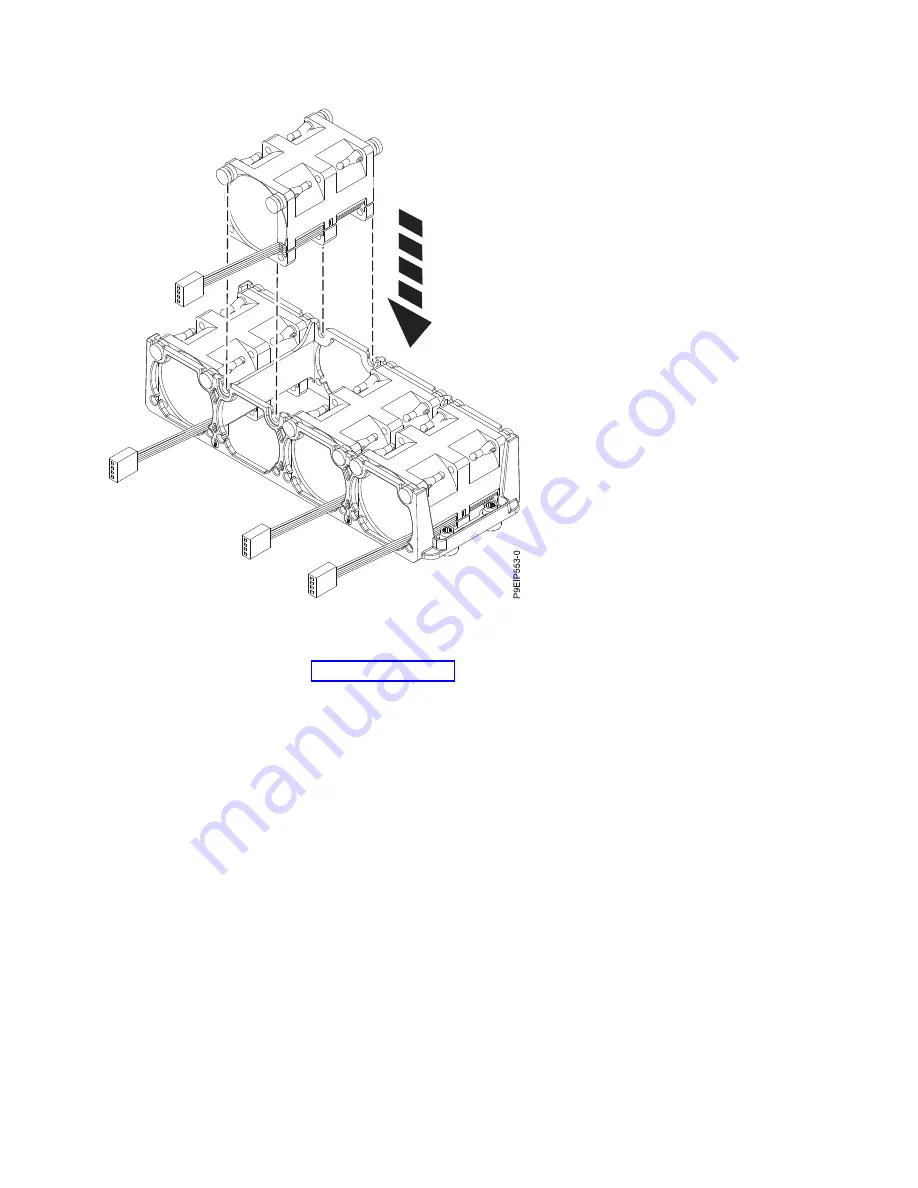

Replace the fan holder into the chassis. Align the holes in the fan holder with the pins in the bottom

of the chassis as shown in Figure 20 on page 22. For the fan holder near the cover switch, temporarily

move the cover switch wires out of the way. When the fan holder is seated into the system, replace

the wires next to the fan holder.

Figure 19. Replacing a fan

Removing and replacing parts in the 9006-12C

21

Summary of Contents for 9006-12C

Page 1: ...Power Systems Servicing the IBM Power System LC921 9006 12C IBM...

Page 2: ......

Page 3: ...Power Systems Servicing the IBM Power System LC921 9006 12C IBM...

Page 16: ...xiv Power Systems Servicing the IBM Power System LC921 9006 12C...

Page 112: ...96 Power Systems Servicing the IBM Power System LC921 9006 12C...

Page 124: ...108 Power Systems Servicing the IBM Power System LC921 9006 12C...

Page 125: ......

Page 126: ...IBM Printed in USA...