3

INSTALLATION AND OPERATING INSTRUCTIONS

SL 35-199, SL 45-260 MODULATING GAS BOILERS

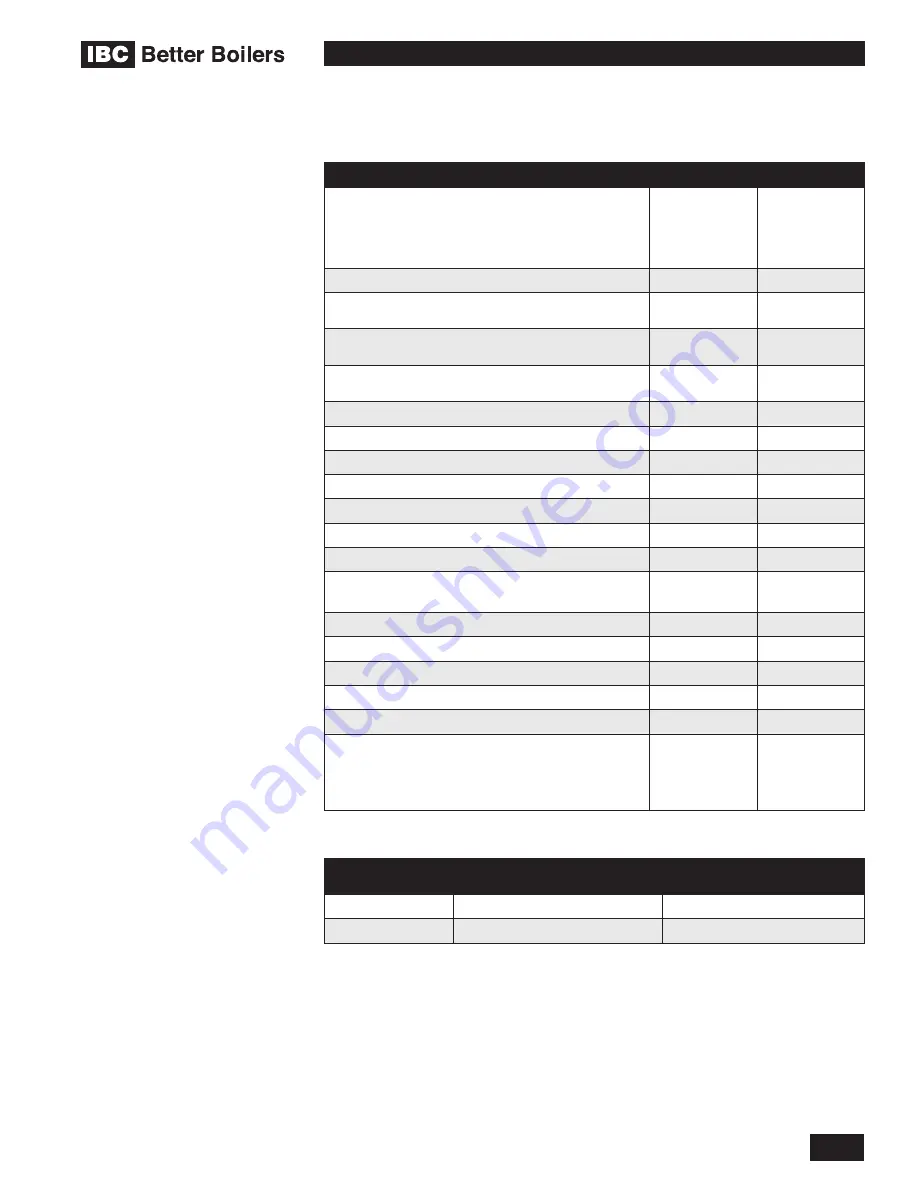

SPECIFICATIONS

SPECIFICATION

SL 35-199

SL 45-260

CSA Input (Natural Gas or Propane*) - MBH

CSA Input (Natural Gas or Propane*) - kW

CSA Output - MBH

CSA Output - kW

35 - 199

10.3 - 58.3

32.7 - 181.3

7.7 - 43

45 - 260

13.2 - 76.2

43.2 - 239

12.7 - 70.0

A.F.U.E.

95%

95%

Minimum gas supply pressure (Natural Gas or

Propane) - inch w.c.

5

5

Maximum gas supply pressure (Natural Gas or

Propane) - inch w.c.

14

14

Power use (120Vac/60Hz) @ full fire - Watts

(without pumps)

92

127

Weight (empty) - lbs/Kg

151 / 69

162 / 74

Pressure vessel water content - USG/Litres

5 / 19

5 / 19

Maximum boiler flow rate - USgpm

25

25

Minimum boiler flow rate - USgpm

6

6

Maximum operating water pressure† - psig

30

30

Minimum water pressure - psig

8

8

Approved installation altitude - ASL

0 - 12,000’

0 - 12,000’

Ambient temperature - Low (°F-°C)

Ambient temperature - High (°F-°C)

32°F / 0°C

122°F / 50°C

32°F / 0°C

122°F / 50°C

Max. relative humidity (non-condensing)

90%

90%

Minimum water temp.

34°F / 1°C

34°F / 1°C

Maximum water temp. (electronic hi-limit)

190°F / 88°C

190°F / 88°C

Maximum water temp. (mechanical hi-limit)

200°F / 93°C

200°F / 93°C

Max. ΔT - supply/return (electronic fence)

40°F

40°F

Maximum equivalent vent length

- 3”

Each side (vent & air intake)

- 4”

(Natural Gas or Propane)

Air intake options: either direct vent or indoor supply

200’

200’

200’

200’

† All boilers are shipped with a 30psig pressure relief valve.

MODEL

NUMBER

NATURAL GAS TO

PROPANE

PROPANE TO NATURAL

GAS

SL 35-199

P-224

P-223

SL 45-260

P-170

P-223

Summary of Contents for SL 35-199

Page 71: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 72: ...NOTES...

Page 73: ...NOTES...