INSTALLATION AND OPERATION INSTRUCTIONS

1-12

SL 35-199, SL 45-260 MODULATING GAS BOILERS

EXHAUST PIPE SIZE

MAXIMUM EQUIVALENT LENGTH

Sched.40; Rigid PPs

3”

200’

4”

200’

90° long sweep elbow

allow 5’ equivalent

90° vent elbow

allow 8’ equivalent

45° elbow

allow 3’ equivalent

PPs 87-90° elbows

use 8’ equivalent

Flexible PPs

3” Flexible (SL 35-199)

160’ (max.) actual lineal x 1.2 = equivalent

3” PPs Flexible (SL 45-260)

60’ (max.) actual lineal x 3.33 = equivalent

4” Flexible

160’ (max.) actual lineal x 1.2 = equivalent

Table 4: Maximum exhaust venting length.

For the

inlet

air – Schedule 40 PVC, CPVC, ABS or PPs piping of any type is

permitted. Use same diameter as Vent pipe.

NOTE:

It is not permitted to add to the exhaust length by transfer of unused

intake allowance.

Combustion air piping - if used - is inserted directly into the 3” female stainless

steel fitting on the top, right side of the boiler and run horizontally or vertically to

the outdoors. Screen material can be placed at the inlet as appropriate for the

environment (e.g. insects, dust).

Care must be taken to ensure adequate separation is maintained between the

air intake inlet and the vent terminal. Refer to the vent terminal configuration

drawings in the Vent Termination section above.

Support should be provided for intake piping, particularly so for horizontal runs

(follow local code).

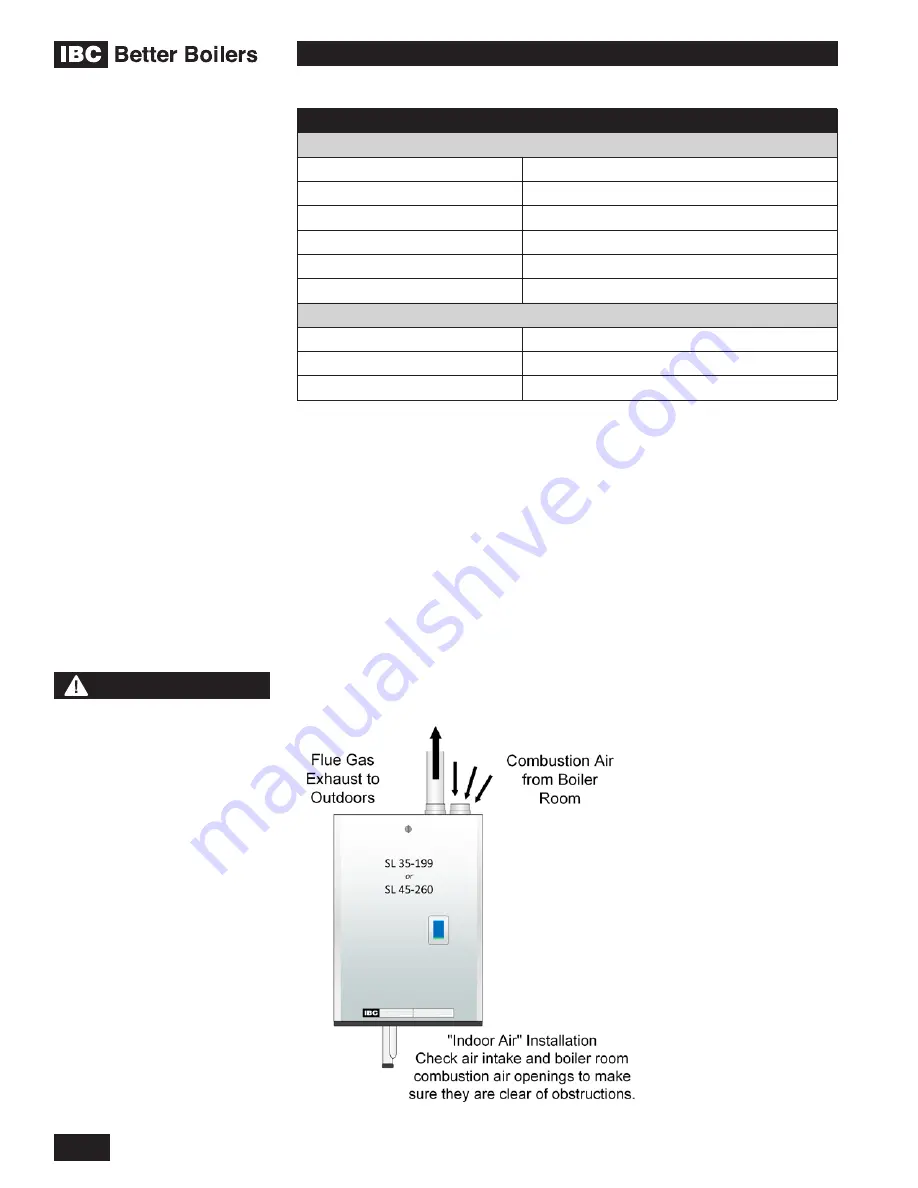

WARNING

When using Indoor

Air options, adequate

combustion air must be

supplied to the boiler room

according to the requirements

of all applicable codes.

Figure 13: Indoor combustion air intake

Summary of Contents for SL 35-199

Page 71: ...SERVICE RECORD DATE LICENSED CONTRACTOR DESCRIPTION OF WORK DONE...

Page 72: ...NOTES...

Page 73: ...NOTES...