21

MAN-88 – UK

§

Use spark plug caps with a resistance of 5K

Ω

to avoid eventual interferences

between the engine ignition and the tachometer and/or telemetry.

The following example should clarify the procedure for the optimization of the sprocket.

Assume to use the engine with Z=10 teeth engine sprocket and that during the preliminary

track tests a Z=72 teeth axle sprocket has been used.

§

From table 1 with Z=10 as engine sprocket and Z=72 on the axle sprocket, a ratio of 7.20 is

found.

§

Make a few laps on the track and, let us assume that you read 11.000 max engine RPM.

§

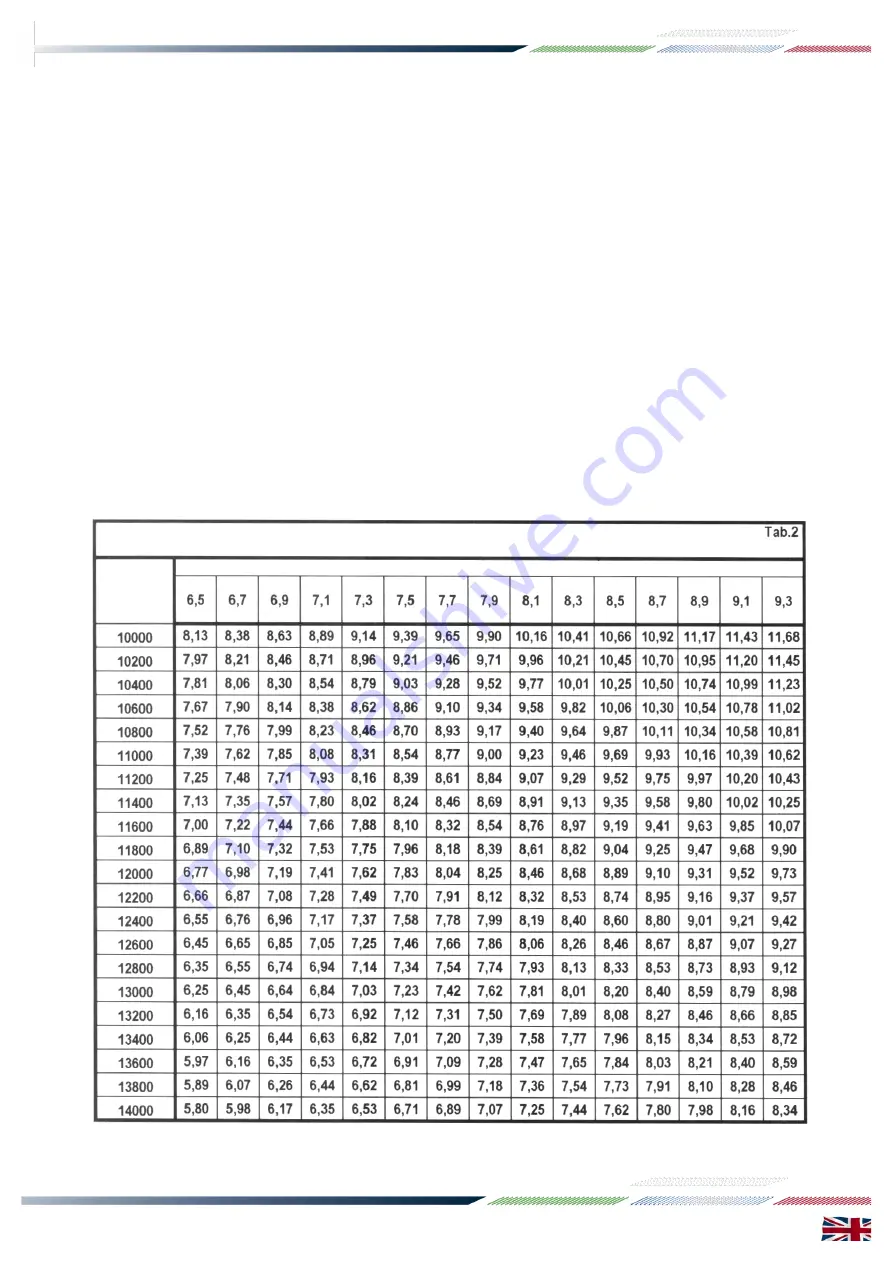

From the table 2 to achieve a max RPM of 12.500 RPM (operating limit for the Gazelle

engine) a sprocket ratio from 8.08 and 8.31should be used (having used, during the tests,

a sprocket ratio of 7.2 and having achieved 11.000 RPM max.)

§

From table.1 , with these values, a sprocket ratio of 10:81 / 10:83 should be used or, having

a Z=11 on the engine sprocket, a ratio 11:90 should be used.

Sprocket ratio to achieve max. 12.500 RPM

Sprocket ratio used during test

Engine max.

RPM during

tests