28

6.

Operation:

Mode

Flow

Chart

29

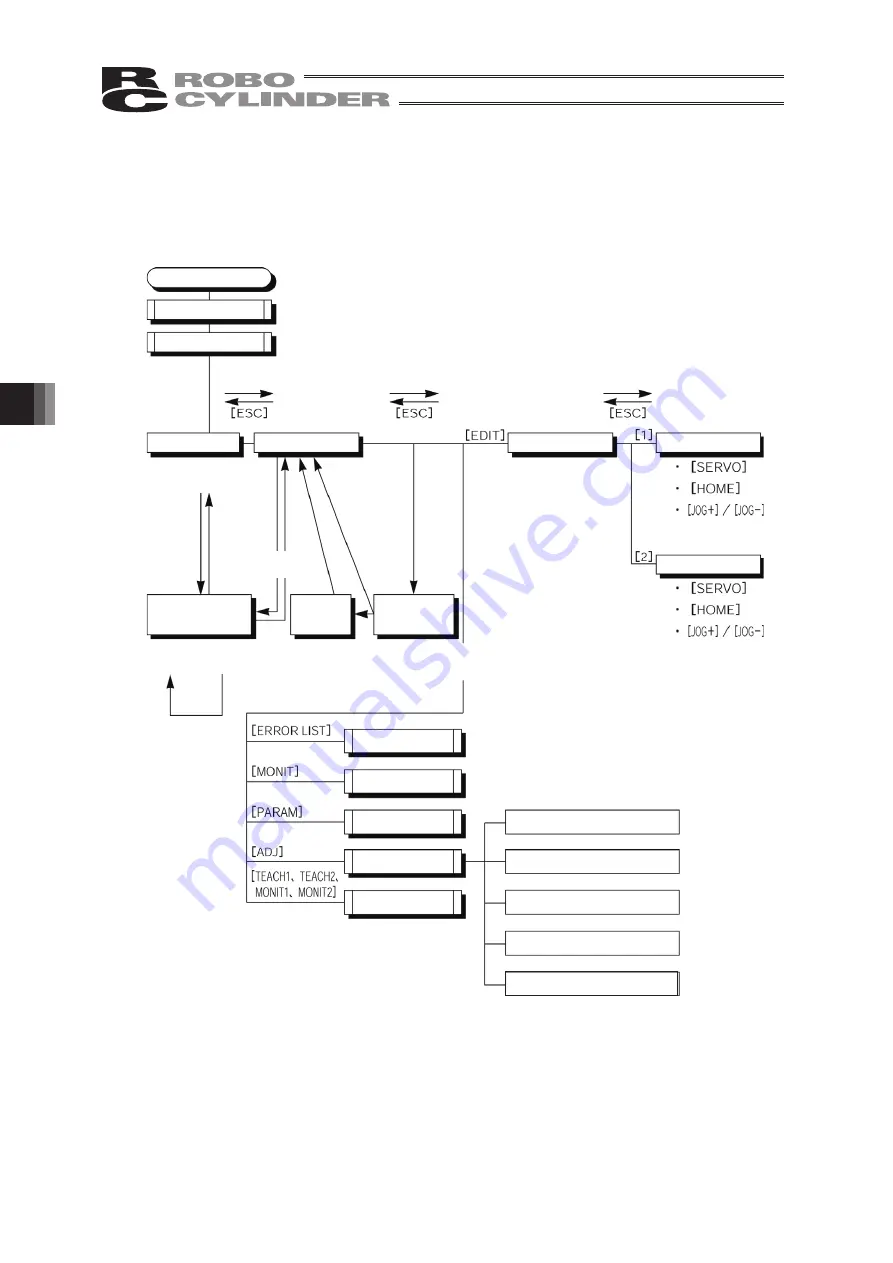

(2) Pulse Train (PCON-PL/PO, ACON-PL/PO and SCON: Pulse Train Mode)

The total picture of operations performed with the Teaching Pendant has the tree structure

as shown below.

To return to the previous screen, press the ESC key.

Power-ON

Set-up Communication

Select Axis

Operation

Start/End

Mode Select

Monitor

Error List

Jog

Return to “Set-up

Communication” when “2.

Reconnection” is selected

Return

1. End

* Before changing the parameter or leaving the

mode, check whether to reset software.

* Displayed only for PCON, ACON and SCON.

* Displayed only when

2 or more axes are

connected

User Parameter

TP Operation Mode

Return

* When the

servo is OFF

Servo OFF

Check

Soft

Reset

* When the

servo is ON

User Adjustment

TP operation mode

Homing

Axis No. Setting

Soft Reset

ErrList Clear

Sip Para

Press & hold

the STOP key

Press & hold

the STOP key

Jog/Inching

Inching

2. Reconnect

2. Reconnect

Summary of Contents for Robo Cylinder CON-T

Page 1: ...Teaching Pendant Instruction Manual Tenth Edition CON T CON TG CON TGS IAI Corporation ...

Page 2: ......

Page 4: ......

Page 8: ......

Page 18: ... ...

Page 24: ...14 4 Functions and Specications of Teaching Pendant 4 2 External View External Dimensions ...

Page 97: ...87 6 Operation Mode Flow Chart Examples of PCON CY Controller On following page ...

Page 98: ...88 6 Operation Mode Flow Chart From previous page On following page ...

Page 99: ...89 6 Operation Mode Flow Chart From previous page On following page ...

Page 100: ...90 6 Operation Mode Flow Chart From previous page ...

Page 117: ......