7

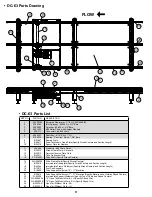

• DC-62 Parts List

REF NO.

PART NO. DESCRIPTION

1

2

3

4

5

055.09745

028.6385

028.2003

029.1025

029.213

Eurodrive Gearmotor - 1-1/2 HP, 230/460/3/60

Idler Sprocket - 60B15H x .515" Bore

Sprocket - 60B15 x 1-3/8" Bore

#60 Roller Chain with Straight Sidebars

Connector Link #60 Chain

6

7

8

9

10

090.2037

010.2028

B-23697

B-22817

B-22516

Shaft Key - 5/16" SQ. x 1" LG.

Bearing - Cast Iron, 4-Bolt, 1-3/8" Bore

Bearing Plate

Drive/Tail Module Tread Plate (Specify Strand Centers and Section Length)

Spacer Plate for Gearbox

11

12

13

14

15

099.456

B-22513

B-22512

B-22511

B-22510

Wearstrip - #60 Chain Guide

Strand Guard Weld - Outboard

Sprocket Tension Plate Weld

Take-Up Bracket Weld

Drive Shaft (Specify Strand Centers)

16

17

18

19

20

B-22509

B-22818

B-22562

B-12672

B-19000

Drive Frame Weld (Specify Strand Centers)

Intermediate Treadplate (Specify Strand Centers and Section Length)

Intermediate Frame Weldment (Specify Strand Centers and Section Length)

Foot Pad Assembly

Drive Support Weldment 15" - 17" Elevation

21

22

23

24

25

B-22819

B-22820

B-22522

B-22532-R

B-22532-L

Drive Support Weldment 17" - 31" Elevation (Specify Elevation and Outside Strand Centers)

Intermediate Support Weldment (Specify Top of Chain and Strand Centers)

12" Open Tail Module Weld (Specify Strand Centers)

Open Tail Stiffener Weld - RH

Open Tail Stiffener Weld - LH

9

8

10

1

7

15

3 6

12

11

24

23

25

18

17

13

2

16

14

20 21

19

22

2

4 5

FLOW

• DC-62 Parts Drawing

Summary of Contents for DC62

Page 15: ...15 ...