EN

English –

5

4.5 - Initial start-up and electrical connections

After powering up the control unit, perform the following checks:

•

After a few seconds, make sure that the “Bluebus” LED (

fig. 16

) flashes regu-

larly with a frequency of about one flash per second.

•

Make sure that the LEDs on the photocells (

fig. 16

) flash (both on TX and RX).

The type of flashing is not important during this stage.

•

Make sure that the flashing light connected to the FLASH output is off.

If the above conditions are not satisfied, switch off the power supply to the con-

trol unit and check the electrical connections previously made.

4.6 - Learning of the devices connected

After the initial power-up, the control unit must be able to recognise the devices

connected to the “

Bluebus

” and “

Stop

” inputs.

IMPORTANT!

– The learning procedure must be performed even if no

device is connected to the control unit.

The control unit is able to recognise the various connected devices individually

through the self-learning procedure and detect possible faults. For this reason it

is necessary to perform self-learning every time a new device is added or an

existing device is removed.

To indicate when the self-learning procedure is required, LEDs

L1

and

L2

on

the control unit (

fig. 16

) emit a number of slow flashes:

01.

Press and hold down

and “

Set

” keys at the same time (

fig. 16

).

02.

Release the keys when LEDs L1 and L2 start flashing quickly (after approx.

3 seconds).

03.

Wait a few seconds for the control unit to complete the device learning

phase.

04.

At the end of this phase, the “Stop” LED must be lit and LEDs “L1” and

“L2” must be turned off (LEDs L3 and L4 may start flashing).

4.7 - Mechanical limiter position learning

After learning the connected devices (paragraph 4.6), the positions of the

mechanical stops must also be learnt (maximum opening and maximum clos-

ing). There are three ways to perform this procedure:

automatic, manual

and

combined.

In automatic mode, the control unit learns the positions of the mechanical stops

and calculates the most suitable offset value for the leafs (SA and SC,

fig. C

).

In manual mode, the eight positions of the mechanical stops (

fig. C

) are pro-

grammed one by one, moving the leafs to the required points. The position to

program is identifiable by the flashing status of one of the eight leds (L1-L8), see

Table 2

.

In combined mode, the automatic procedure can be performed and then, using

the manual procedure, one or more positions may be modified, with the excep-

tion of positions “

0

” and “

1

” (

fig. C

) which coincide with the positions of the

mechanical stops.

4.7.1 - Learning in automatic mode

01.

Press and hold keys “

Set

” and “

” at the same time.

02.

Release the keys when leds “

L3

” and “

L4

” start flashing quickly (after

approx. 3 seconds).

03.

Ensure that the automation completes the following sequences of ma -

noeuvres:

a -

Low speed closure of gearmotor M1 through to the mechanical stop

b -

Low speed closure of gearmotor M2 through to the mechanical stop

c -

low speed opening of gearmotor M2 and gearmotor M1 through to the

mechanical stop

d -

High speed closure of gearmotors M1 and M2

Warnings:

– If the first manoeuvre (

a

) does not close the leaf controlled by motor M1 but

closes the one controlled by M2, press key “

” or “

” to stop the learning

phase. At this point, invert the connections of motors M1 and M2 on the ter-

minals on the control unit and then those of the respective encoders; after

this start the procedure from point 01;

– If the first two manoeuvres (

a

and

b

) are not “closing” but are “opening”,

press key “

” or “

” to stop the learning phase. At this point, on the gear-

motor that completed the opening manoeuvre, invert the polarity of the two

wires of gearmotor M1 (terminals 7 and 9) and of M2 (terminals 10 and 12)

and then start the procedure from point

01

;

04.

At the end of the Closing manoeuvre of the 2 motors (

d

), leds “

L3

” and “

L4

”

turn off to indicate the that the procedure has been completed correctly.

Warnings:

– During the automatic learning procedure, if a photocell trips or a device con-

nected to the “stop” input is activated, the procedure is interrupted and led

L1 starts flashing. To resume the learning process, the procedure must be

started again from point

01

;

– The automatic learning procedure can be repeated at any time, also after

installation; for example following modifications to the position of the

mechanical stops.

4.7.2 - Learning in manual mode

Caution!

–

From step 03 onwards:

– to move from led L1 to L8, briefly press key

or

(the led flashes to indi-

cate the current position);

– to move the motor in one or the other direction, press and hold key

or

.

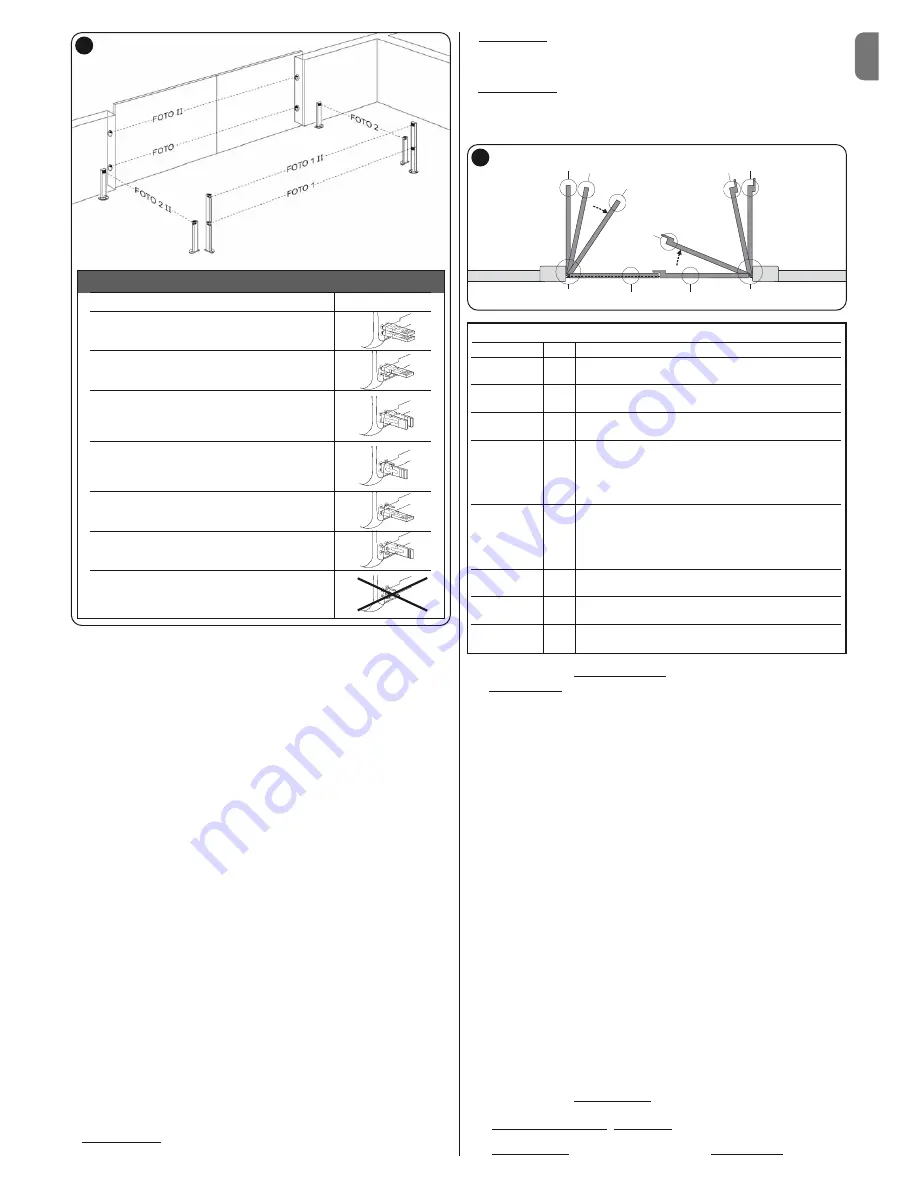

B

TABLE 2

-

PHOTOCELL ADDRESSES

Photocell

Jumpers

FOTO

External photocell h = 50 with trip on

closure (stops and inverts movement)

FOTO II

External photocell h = 100 with trip on closure

(stops and inverts movement)

FOTO 1

Internal photocell h = 50 with trip on closure

(stops and inverts movement) and opening

(stops and restarts when photocell is disengaged)

FOTO 1 II

Internal photocell h = 100 with trip on closure

(stops and inverts movement) and opening

(stops and restarts when photocell is disengaged)

FOTO 2

Internal photocell with trip on opening

(stops and inverts movement))

FOTO 2 II

Internal photocell with trip on opening

(stops and inverts movement)

FOTO 3

CONFIGURATION NOT ADMITTED

TABLE 2

Position

Led

Description

Position 0

(motor 1)

Position 0

(motor 2)

Position SA

(motor 2)

Position A

(motor 1)

Position A

(motor 2)

Position SC

(motor 1)

Position 1

(motor 1)

Position 1

(motor 2)

Maximum closing position: when leaf 1 reaches closing

mechanical stop

Maximum closing position: when leaf 2 reaches closing

mechanical stop

Opening offset: when leaf 2 passes this position the opening

of leaf 1 begins

Desired opening position: position at which the leaf connected

to motor 1 must stop at the end of an opening manoeuvre.

This position does not need to coincide with the opening

mechanical stop but can be chosen as desired between the

positions 0 and 1

Desired opening position: position at which the leaf connected

to motor 2 must stop at the end of an opening manoeuvre.

This position does not need to coincide with the opening

mechanical stop but can be chosen as desired between the

positions 0 and 1

Closing offset: when leaf 1 reaches this position, leaf 2 begins

to close

Maximum opening position: when leaf 1 reaches the opening

mechanical stop

Maximum opening position: when leaf 2 reaches the opening

mechanical stop

L1

L2

L3

L4

L5

L6

L7

L8

0

1

1

A

SC

SA

A

0

M1

M2

C

POSITIONS

Summary of Contents for HK7024

Page 2: ......

Page 25: ...IX 1 2 3 4 320 mm 210 mm 290 mm ...

Page 27: ...XI 1 2 a b 3 9 5 OK OK b a 9 b a a b x 4 c a 4 1 2 3 4 90 90 10 7 6 8 ...

Page 28: ...XII 9 1 2 a b 3 10 5 b x 4 c a 4 8 b a 10 1 2 3 13 11 6 OK OK 7 ...

Page 29: ...XIII 1 2 90 3 90 12 A 90 2 1 3 12 B 4 OK 3 NO 2 NO 11 1 3 2 5 4 ...

Page 31: ...6 1 2 8 7 15 1 3 5 1 2 2 4 XV ...

Page 32: ...XVI 16 1 2 7 6 17 L1 OPEN STOP CLOSE L2 L3 L4 L5 L6 L7 L8 ...

Page 33: ...XVII 1 2 1 2 18 1 3 5 1 2 2 2 1 4 19 1 2 ...

Page 34: ...XVIII 1 2 20 1 4 1 2 3 2 ...