18

P/N 42-9551

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

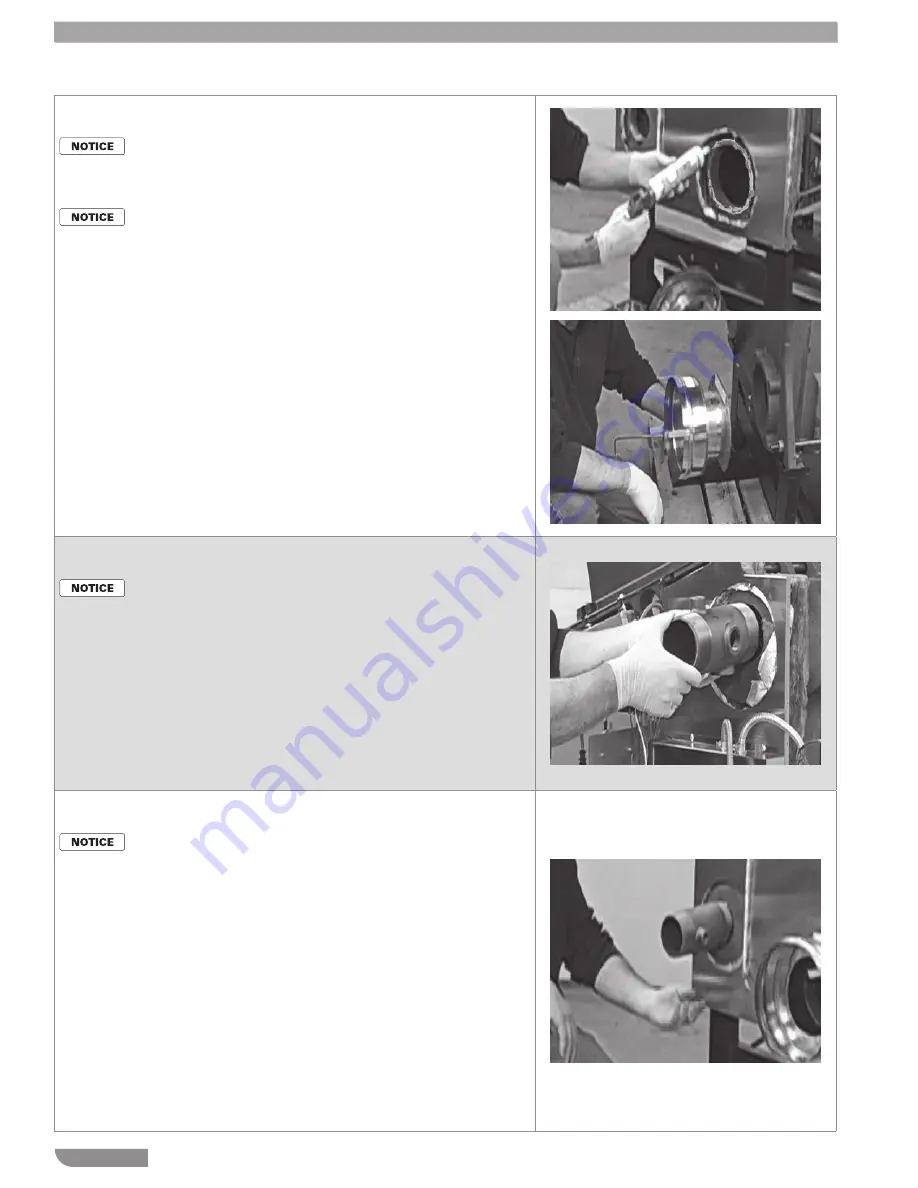

Step 45

Install flue adapter

Make sure the flue adapter

condensate nipple is located

at the BOTTOM when in-

stalled.

Rubber gloves are recom-

mended for this procedure.

1. Apply silicone RTV to the flue adapter

mounting boss.

2. Position the flue adapter on the boss

and insert the four mounting bolts.

The condensate nipple must be

pointed DOWN.

Step 46

Install supply nipple

The boiler is supplied with

two nipples that include

three control tappings. The

nipples are identical, but they

must be positioned differ-

ently.

1. Apply pipe dope to one of the 3-inch

nipples and the upper right tapping

on the rear of the boiler.

2. Install the supply nipple in the tap-

ping.

3. When the nipple is tightened, it must

be in the orientation shown — the

½” tapping must be on top, with a

¾” tapping at the right and at the

bottom.

4. The ½” tapping is used for the 10K

supply sensor.

Step 47

Install supply nipple

The boiler is supplied with

two nipples that include

three control tappings. The

nipples are identical, but they

must be positioned differ-

ently.

1. Apply pipe dope to one of the other

3-inch nipple and the lower left tap-

ping on the rear of the boiler.

2. Install the return nipple in the tap-

ping.

3. When the nipple is tightened, it must

be in the orientation shown — the

½” tapping must be on right, with a

¾” tapping at the bottom and at the

left side.

4. The ½” tapping is used for the 10K

return sensor.

5. The ¾” bottom tapping is used for the

boiler drain.

6. The ¾” side tapping should be

plugged unless used for a special

purpose.