11

ACTIVATING THE SYSTEM

Turn on the Source Water

NOTE:

Make sure all water lines and fittings are secure

and free from leakage.

1. Open source water supply valve. Check for leakage.

2. Open product water faucet and let water flow to drain

for at least 10 minutes. This will expel the air from the

system.

3. Close product water faucet. In 5 minutes, check the

connections for leaks and correct if necessary.

Connect The Smartap

®

Monitor Battery

NOTE:

Battery is mounted inside the module cover.

Battery may be connected prior to installation.

1. Loosen three mounting bracket screws. Gently pull

module cover up and away from the module body.

2. Connect the battery by pressing the clip onto the

battery terminals (See Page 13, Figure 11).

3. Replace module cover and tighten bracket screws.

4. To test connection, activate monitor by pressing test

button or opening product water faucet. If an indicator

light illuminates, connection is good.

SERVICING THE SYSTEM

MAINTENANCE - WARRANTY INFORMATION

Recommended Service Intervals

Hydrotech

®

Warranty

Replace filters as required based on Smartap

®

Water Flow Monitor indications

or every 6 to 12 months depending on feed water quality.

System: 2 years limited

Smartap

®

: 5 years

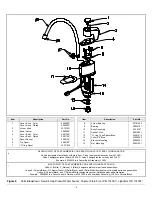

FAUCETS

Non-Air Gap Faucet

Part Number

Non-Air Gap Faucet

Part Number

Non-Air Gap Faucet

Part Number

Stainless Steel, Faucet Only

Stainless Steel, with Light Bar

40301007

11702002

Chrome, Faucet Only

Chrome, with Light Bar

40301002

11702001

Polymer, Plain Front

Polymer, Light Bar

1140010*

1140032*

* Color Suffix Codes: 0 (Chrome/Black), 1 (White), 2 (Chrome/White), 3 (Almond), 4 (Black), 5 (Chrome/Black), 6 (Satin/Black), 7 (Chrome/White), and

8 (Satin/White). Codes 0, 2, 6, and 8 designate electro-plated faucets. Codes 5 and 7 designate vacuum-metalized faucets

PARTS AND SERVICE ARE AVAILABLE THROUGH YOUR HYDROTECH

®

DEALER.

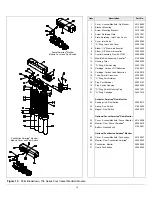

ROUTINE MAINTENANCE

RECOMMENDATIONS

HAVE ALL COMPONENTS ON HAND AND READY BEFORE BEGINNING PROCEDURE.

A CLEAN WORK AREA AND EQUIPMENT ARE ESSENTIAL TO PROPERLY CLEAN AND/OR SANITIZE THE SYSTEM.

(I.e., CLEAN HANDS, TOOLS, WORK SURFACE, AND CONTAINERS)

SERVICE REQUIREMENTS

To insure the system operates at its optimum level,

certain routine maintenance must be performed.

Frequency of maintenance performance will depend on

feed water quality and level of system usage.

CLEAN:

Each time filters are replaced

SANITIZE:

At least once every 12

months.

EQUIPMENT NEEDED

Safety glasses

Rubber gloves, sanitary

Wash Cloth, Clean and Lint-free

Household bleach - Unscented Only

(5 1/4% sodium hypochlorite)

Liquid dish soap

Plastic bucket, Plastic bowl

“O” Ring Lube FDA Approved

(P/N 30300026)

REPLACEMENT FILTER SETS

“O” RINGS

P/N 41400011 Carbon Filter, VOC Reduction (White Caps)

P/N 41400010 Carbon Filter, Lead Reduction (Black Caps)

P/N 34201010 Carbon Cartridge

P/N 34201026 Filter Housing