8

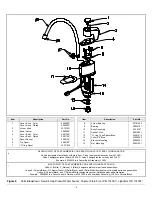

PRODUCT WATER FAUCET INSTALLATION - POLYMER FAUCET

Install on flat surface at least 2 7/16" in diameter. Unused 1 1/4"- 1 7/16" opening is ideal.

New Faucet Installation

Refer to Faucet Site Preparation, Page 5.

Replacement Faucet Installation

Verify size of existing hole. If hole measures 1 7/16",

faucet may be installed without changes. If hole

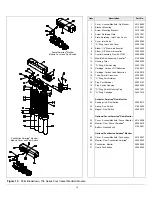

measures 1 1/4", remove two locator tabs (See Figure 8)

prior to installation by breaking them off at faucet base.

Figure 8

Faucet Locator Tabs.

NOTE:

Item callouts refer to Page 9, Figure 9 unless

otherwise

noted.

1. Remove mounting nut (Item 23) and bracket (Item 22)

from faucet.

2. Install 3/8" blue tube into blue collet in faucet base.

3.

Plain Front:

Insert tube into mounting hole and place

faucet over hole. Align faucet body with narrow face

forward.

Light Bar:

Insert tube and monitor cord into

mounting hole and place faucet over hole. Align

faucet body with light bar forward.

NOTE:

Do not pinch, kink, pull, or otherwise deform

monitor cord.

4. Install mounting bracket and nut below sink. Tighten

mounting nut

by hand

so that faucet does not move.

Do not over tighten.

NOTE:

Faucet is packaged for right-hand operation. For

left-hand operation, realign knob by completing

Step 5.

NOTE:

Item callouts in Step 5 refer to Page 9, Figure 9.

5. Align faucet knob for left-hand operation.

a. Rotate knob to rear of faucet (closed position).

b. Remove knob cover (Item 1) using a thin, flat tool

to pry cover from knob.

c. Remove knob attachment screw (Item 2) using a

Phillips-head screwdriver.

d. Remove knob (Item 3) by pulling it (by hand)

straight up. Rotate knob counterclockwise 90º,

and re-install.

e. Install knob attachment screw. Tighten screw

until free movement (i.e., rocking) is eliminated.

f. Snap knob cover into place.

6. Install spout into faucet body. Lubricate “O” ring with

FDA approved Silicone Lubricant. Align spout with

faucet outlet, gently push spout to bottom of outlet.

7. Connect 3/8" blue tubing to swivel elbow located on

rear of module.

8.

Light Bar:

Connect monitor cord to module. Insert

cord into a telephone-style connector located on

Filtration Module cover (See Page 6, Figure 6).

NOTE:

The basic installation is complete and system is

ready for activation (See Page 11).

CLEAN FAUCET SURFACE USING DISHWASHING DETERGENT ONLY. DO NOT USE ABRASIVES OR SOLVENTS.