INTRODUCTION

NSF

R

THIS GUIDE IS APPLICABLE TO ALL AQUAFIER

®

MODELS

TABLE A

SYSTEM CONFIGURATION

FAUCET TYPE

Filtration Unit

Flow Monitor

Chrome

Stainless or Polymer

None

Faucet Smartap

®

10403002

10403102*

10402102*

Pushbutton Smartap

®

10403001 10403101* 10402101*

Aquafier

®

4 Vessel

Unitary Manifold

None 10401000

10401100* 10402100*

* System Tested and Certified By NSF International Against ANSI/NSF 53 and ANSI/NSF 42.

CERTIFIED CONTAMINANT REDUCTION PERFORMANCE

SYSTEM TESTED AND CERTIFIED BY NSF INTERNATIONAL AGAINST ANSI/NSF 53 AND ANSI/NSF 42 FOR REDUCTION OF

ASBESTOS LEAD

PARTICULATES CYSTS*

TURBIDITY

AESTHETICS: TASTE, AND ODOR CHLORINE REDUCTION CLASS I VOLATILE ORGANIC CHEMICALS (VOC's)

* Certification for reduction of Cysts including Cryptosporidium parvum ococysts and cysts of Giardia and Entamoeba.

SYSTEM STATISTICS

SYSTEM CAPACITY

without Smartap

®

Flow Monitor

SYSTEM CAPACITY

with Smartap

®

Flow Monitor

SERVICE FLOW RATE

at the Manifold Unit Outlet

3969 Litres (1050 gallons)

6615 Litres (1750 gallons)

1.9 Liters/minute (0.5 Gallons/minute)

PERFORMANCE INDICATOR

SMARTAP

®

WATER FLOW MONITOR

The optional Smartap

®

Monitor indicates filter cartridge status by measuring the volume of water passing through the

Aquafier

®

Water Treatment System. When water is dispensed, it flows through the system actuating the monitor and

recording the elapsed time for each dispense. Monitor indication is based on the cumulative number of gallons passed

through the system (elapsed time multiplied by flow rate). A green light indicates filters are functioning normally.

A yellow light indicates filters are nearing useful capacity and should be replaced.

Disconnecting the battery from the clip resets the Monitor. Installing a new battery each time filter cartridges are replaced

ensures an accurate indication of system performance and a continuing supply of high quality drinking water.

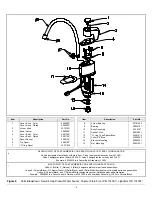

FAUCET ACTUATED SMARTAP

®

FLOW MONITOR

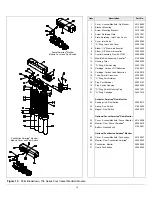

PUSHBUTTON ACTUATED SMARTAP

®

FLOW MONITOR

A light illuminates in a Light Bar each time a faucet

or additional point-of-use device is activated.

Light Bar Assembly is located at faucet base (Chrome or

Stainless Steel) or front of faucet body (Polymer).

Power is provided by nine volt alkaline battery.

A light illuminates when the test button is pressed.

Pushbutton Actuator and Indicator Lights

are located on the Manifold Cover.

Power is provided by nine-volt alkaline battery.

I