10

2A. Water Supply & Chemical Mixing– Manual Fill:

•

Pour up to 12 gallons (45.4 Liters) of hot water into the solution tank at the front of the machine.

The

water temperature cannot exceed 130

°°°°

F or 54°C.

•

Measure and add the appropriate amount of the desired liquid chemical to the water in the solution tank.

The amount of chemical will vary depending on the type of chemical used, the amount of water in the

tank, and the material being cleaned; consult the chemical packaging for specific mixture ratios.

•

Powdered chemicals should be dissolved in water before adding to the water in the solution tank.

DO NOT RUN OUT OF WATER WHILE USING THE MACHINE! Ensure that the tank

contains enough water to complete each job. If the water level is low: stop cleaning, turn off the

pump, and refill the tank. Running the pump dry will damage the pump and void the warranty.

2B. Optional Auto-Fill System - Water Supply & Chemical Dilution:

•

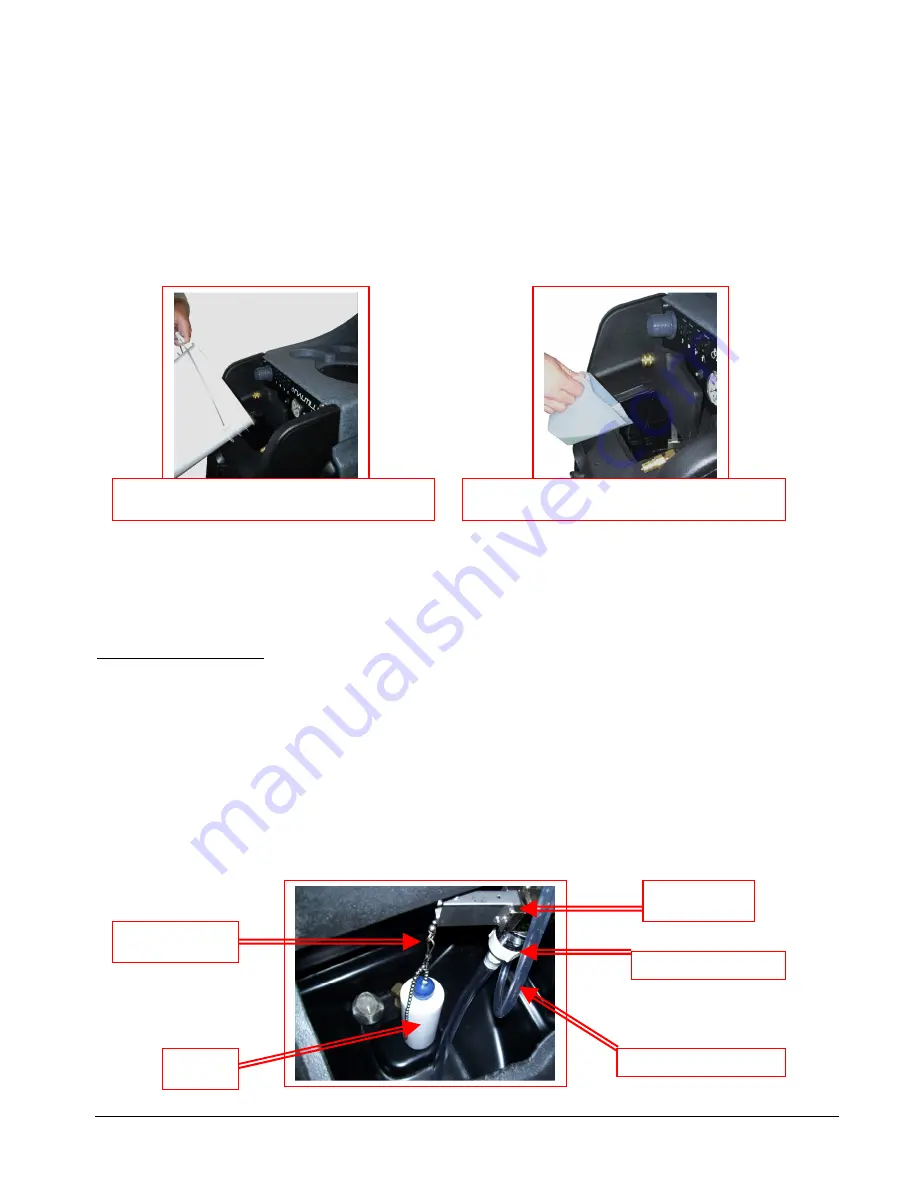

The chemical dilution rate is controlled by the metering tip, and the dilution rate can only be changed by

changing the metering tip (See “How to Change the Metering Tip” on Page 11 for instructions.)

Chemical Feed Setup:

•

Remove the chemical feed hose from the solution tank. Make sure float is attached to valve and hanging

freely, above the bottom of the solution tank. Adjust float height to maintain adequate water level.

•

Place the end of the chemical feed hose into a container of liquid chemical.

•

If the tip is removed, and the proportioning system operated with no tip, the dilution rate will be 8:1, the

equivalent to adding 16-1/4oz of chemical to each gallon of water. (125ml per liter)

•

The recommended tip for use with the MX3-200HE is the turquoise tip with a dilution rate of 256:1. This

means that for each gallon of water flowing into the machine, 1/2 ounce of chemical will be added.

(3.91ml of chemical per liter of water)

•

If a fresh water rinse with no chemical is desired, simply leave the chemical feed hose inside the

solution tank.

Proportioning Valve

Chemical Feed Hose

Float

Float Valve

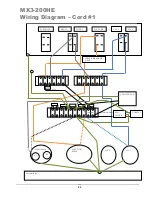

Pour appropriate amount of hot water into

solution tank

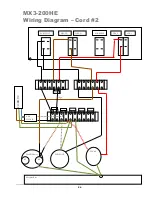

Add appropriate amount of chemical to water

in solution tank

Float Hanger

Summary of Contents for Nautilus MX3-200HE

Page 1: ...1 LMANN09 Revised 02 16 2018 Nautilus MX3 200HE Operating Manual ...

Page 37: ...37 OPTIONAL AUTO FILL FLOAT VALVE ASSEMBLY NM5740 ...

Page 38: ...38 Optional Pump Out Pump AP37 PARTS ASSEMBLY ...

Page 39: ...39 1 2 6 7 8 9 11 3 8 9 12 4 4 3 10 5 15A 8 9 8 9 39 2 ...

Page 43: ...43 48 49 49 47 47 47A 47 47 47A 47A 51 51 37 9 54 64 52 VACUUM MOUNTS CONNECTIONS 9 54 64 ...

Page 48: ...48 96 91 97 9 94 105 OPTIONAL PUMP OUT CONNECTIONS 99 95 93 103 ...

Page 49: ...49 FLOW 81 92 91 99 96 97 105 13 14A 14 95 OPTIONAL PUMP OUT PARTS 1 9 97 103 39 9 ...

Page 50: ...50 HEATER PARTS 111 113 114 112 2 115 2 116 2 42 42A 98 111 ...