© Hydra-Flex, Inc. 2017

Page | 8

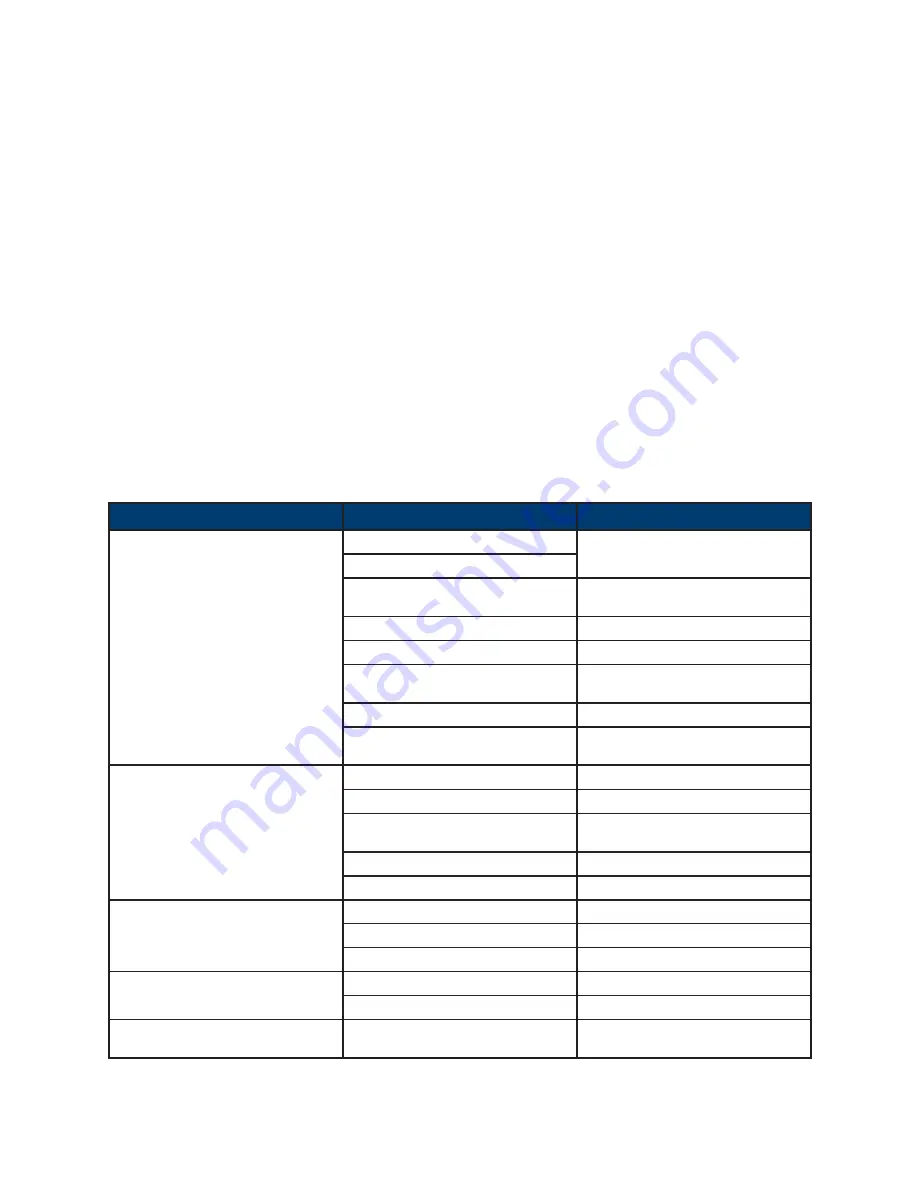

TROUBLESHOOTING

The AQUA-LAB is supplied with the following tools to assist in set up and troubleshooting:

• Vacuum gauge for checking the vacuum at the chemical injector hose barb,

• Back Pressure Gauge for measuring back pressure downstream of the injector.

PROBLEM

POTENTIAL CAUSED

SOLUTIONS

Pump Operates, but delivers little or no

water

Inlet Restriction

Check all in-line filters and inlet plumbing

for restrictions

Low line voltage

Inadequate water supply

Check pressure on inlet side of pump to

be sure positive pressure is maintained

Undersized piping

Replace with larger piping

Leak on the Inlet side

Make sure connections are tight

Worn or defective pump parts

Replace worn parts or entire pump,

Clean parts if required

Pump not primed

See priming instructions

Incorrect Motor rotation

Reverse motor rotation by interchanging

any two leads

Pump won’t start or run at full speed

Blown fuse or circuit breaker

Replaced fuses or close circuit breaker

Defective Motor Starter contactor

Replaced motor starter contactor

Incorrect Motor Voltage

Voltage must be within 10% of motor

rated voltage

Defective motor

Replace motor

Pump components damaged

Replace worn part or entire pump

Excessive Noise from Pump

Pump not secured firmly

Secure properly

Restricted Inlet

Clean or correct restriction

Cavitation (Sounds like marbles in pump)

Increase inlet size

Pump Leaks

Worn mechanical seal

Replace shaft seal

Worn o-ring seals

Replace

Injector is not drawing chemical -

Passes

Vacuum Pressure check test

Clogged chemical feed

Check chemical hose, foot valve, meter-

ing tip and hose barb for debris or clogs

INDIVIDUAL INJECTOR FLOW RATE MEASUREMENT

1.

Attach a short section of tubing (3-5 ft) to the outlet of the injector that you want to measure the flow

rate of.

2.

Turn on the Aqua-Lab pump and the solenoid valve for the Injector being tested. If possible have

someone assist by turning them on while you keep the water from the short section of hose pointed

in a safe direction.

3.

Using a 2 liter graduated cylinder (or other large graduated cylinder) and a stop watch (watch or cell

phone with a stop watch)

•

Make sure the graduated cylinder is empty and that the stop watch is cleared.

•

Direct the flow of water from the tube into the graduated cylinder and start the stop watch the

instant you start adding water to the cylinder.

•

Stop the timer when the cylinder is at least half full, preferably at a whole number level (ie. 1 liter,

2 liters)

•

Divide the number of liters by the time in seconds then multiply by 15.85 – this will result in how

many Gallons per minute (GPM)