HYDAC FILTER SYSTEMS GMBH

Industriegebiet

Postfach

1251

66280 Sulzbach/Saar

66273 Sulzbach/Saar

Germany Germany

Phone: +49 (0) 6897 509 01

Central

Fax:

+49 (0) 6897 509 9046

Technical Department

Fax:

+49 (0) 6897 509 577

Sales Department

Internet: www.hydac.com

E-mail: [email protected]

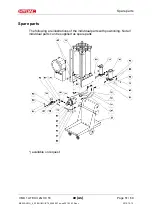

Summary of Contents for VarnishMitigation Unit

Page 59: ......