9

−

6

114

Use and maintenance manual DM-1215

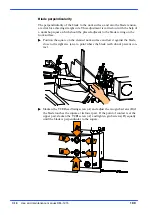

Blade structure

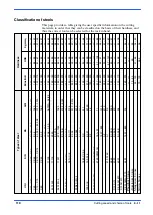

The most commonly used blades are the bimetal types, i.e. manufactured with a

silicon steel body and having a high fatigue strength, and super high-speed steel

teeth; the two parts are welded by electronic or laser-welding.

Standardised teeth types are termed M2 and M42; the difference being that M42

teeth are harder due to the addition of cobalt to the steel used to make the teeth.

Key

Mo Molybde

num

Ni Nickel

Si

Silicon

V

Vanadium

W

Tungsten

Al

Aluminium

C

Carbon

Co Cobalt

Cr Chromium

Mn Manganese

HSS M2

HSS M42

C

Mn

Si

W

Mo

V

Ni

Co

Al

HRC

Cr

0,47 0,75 0,22 1,00

1,00 0,12 0,52

0,08 45

−

50

0,85 0,25 0,30 4,15

6,37 5,00 1,92

64

−

66

1,07 0,25 0,20 3,75 1,50 9,50 1,15

8,00

67

−

69

ËËËËË

ËËËËË

ËËËËË

ËËËËË

ËËËËË

ÊÊÊÊ

ÊÊÊÊ

ÊÊÊÊ

ÏÏÏÏÏ

ÏÏÏÏÏ

HRC 67

−

68

HRC 45

−

50

ËËËËË

ËËËËË

ËËËËË

ËËËËË

ÊÊÊÊ

ÊÊÊÊ

ÊÊÊÊ

ÏÏÏÏÏ

ÏÏÏÏÏ

HRC 65

−

66

HRC 45

−

50

TYPE OF

BLADE

The numbers in the columns indicate the % content of the element in the steel.

Blade types

The blades mounted on the

DM-1215

are 3.440 x 27 x 0,9 mm.; the length can

vary between 3.420 mm. and 3.460 mm., thanks to the blade tensioner device. The

blades, however, apart from size and tooth pitch, are differentiated by other

geometrical characteristics which determine their specialised uses:

tooth cutting angle (rake), can be 0

°

or positive;

the tooth pitch can be constant or variable;

the set, i.e. the various teeth alignments, have many possible configurations.

N.B.

Summary of Contents for DM-1215

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ DM 1215 EN ...

Page 2: ......

Page 4: ......

Page 34: ......

Page 53: ...6 7 52 Diagrams exploded views and replace Standardised Wiring Diagrams ...

Page 54: ...6 8 53 Use and maintenance manual DM 1215 ...

Page 55: ...6 9 54 Diagrams exploded views and replace ...

Page 56: ...6 10 55 Use and maintenance manual DM 1215 F6 F7 F8 F3 F4 F5 RT4 ...

Page 57: ...6 11 56 Diagrams exploded views and replace F1 F2 F9 ...

Page 58: ...6 12 57 Use and maintenance manual DM 1215 S4 KSTO S8 S4 K01 ...

Page 59: ...6 13 58 Diagrams exploded views and replace KSTO KSTO RT4 ...

Page 61: ...6 15 60 Diagrams exploded views and replace ...

Page 62: ...6 16 61 Use and maintenance manual DM 1215 ...

Page 63: ...6 17 62 Diagrams exploded views and replace ...

Page 64: ...6 18 63 Use and maintenance manual DM 1215 ...

Page 65: ...6 19 64 Diagrams exploded views and replace ...

Page 66: ...6 20 65 Use and maintenance manual DM 1215 ...

Page 67: ...6 21 66 Diagrams exploded views and replace ...

Page 68: ...6 22 67 Use and maintenance manual DM 1215 ...

Page 69: ...6 23 68 Diagrams exploded views and replace ...

Page 70: ...6 24 69 Use and maintenance manual DM 1215 ...

Page 71: ...6 25 70 Front flywheel assembly ...

Page 74: ...6 28 73 Use and maintenance manual DM 1215 Motor flywheel assembly ...

Page 77: ...6 31 76 Cutting head cover ...

Page 79: ...6 33 78 Vice assembly ...

Page 81: ...6 35 80 Base assembly ...

Page 83: ...6 37 82 Control panel ...

Page 85: ...6 39 84 Fixed work table and turntable ...

Page 88: ...6 42 87 Use and maintenance manual DM 1215 Cylinder unit ...

Page 90: ...6 44 89 Use and maintenance manual DM 1215 Laser and lamp group ...

Page 92: ......

Page 132: ......

Page 136: ......