8

−

3

107

Maintenance and choice of consumables

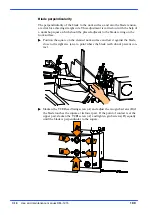

apply lubricating oil to the rotating platform's internal circuit using ball valve

oiler situated in the rear part of the fixed platform.

Monthly

This section lists the operations to be carried out for the monthly maintenance of

the machine:

check the perpendicularity of the blade to the work surface; if it is necessary

to adjust the blade setting, follow the instructions set out in Chapter 7;

check on blade orthogonality with respect to the workpiece rest shoulder; if

adjustment is necessary, proceed as instructed in Chapter 7;

check that the 0° notch on the work table is in line with the graduation on the

turntable; if not, readjust by regulating the 0° stop; then re-check that the

blade is perpendicular and orthogonal;

check the precision of the 45° and 60° left stops and the 45° right stop; if

out-of-set, adjust following the steps indicated in Chapter 7;

check the state of the widia inserts and the blade steady button; replace if

worn or chipped; check their positions and adjust if necessary (see Chapter

7);

thoroughly clean the bottom of the water tank and the electropump filter;

controls the hydraulic brake oil level.

Maintenance of working parts

DM-1215

maintenance engineers must pay particular attention to functioning

elements such as the blade tensioning cylinder (already considered in chapter 7),

loading, the air treatment unit, the pneumatic vice (if AUTOMATIC VICE

version) and the hydraulic brake.

The transmission box equipping the machine needs no maintenance.

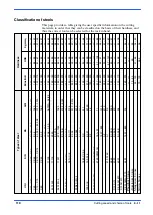

Consumable materials

Only specified oils must be used for the hydraulic and pneumatic and for

lubricant/coolant devices. Below is a list of compatible oils for each of these

circuits.

Summary of Contents for DM-1215

Page 1: ...USE AND MAINTENANCE MANUAL YEAR OF MANUFACTURE ______________ DM 1215 EN ...

Page 2: ......

Page 4: ......

Page 34: ......

Page 53: ...6 7 52 Diagrams exploded views and replace Standardised Wiring Diagrams ...

Page 54: ...6 8 53 Use and maintenance manual DM 1215 ...

Page 55: ...6 9 54 Diagrams exploded views and replace ...

Page 56: ...6 10 55 Use and maintenance manual DM 1215 F6 F7 F8 F3 F4 F5 RT4 ...

Page 57: ...6 11 56 Diagrams exploded views and replace F1 F2 F9 ...

Page 58: ...6 12 57 Use and maintenance manual DM 1215 S4 KSTO S8 S4 K01 ...

Page 59: ...6 13 58 Diagrams exploded views and replace KSTO KSTO RT4 ...

Page 61: ...6 15 60 Diagrams exploded views and replace ...

Page 62: ...6 16 61 Use and maintenance manual DM 1215 ...

Page 63: ...6 17 62 Diagrams exploded views and replace ...

Page 64: ...6 18 63 Use and maintenance manual DM 1215 ...

Page 65: ...6 19 64 Diagrams exploded views and replace ...

Page 66: ...6 20 65 Use and maintenance manual DM 1215 ...

Page 67: ...6 21 66 Diagrams exploded views and replace ...

Page 68: ...6 22 67 Use and maintenance manual DM 1215 ...

Page 69: ...6 23 68 Diagrams exploded views and replace ...

Page 70: ...6 24 69 Use and maintenance manual DM 1215 ...

Page 71: ...6 25 70 Front flywheel assembly ...

Page 74: ...6 28 73 Use and maintenance manual DM 1215 Motor flywheel assembly ...

Page 77: ...6 31 76 Cutting head cover ...

Page 79: ...6 33 78 Vice assembly ...

Page 81: ...6 35 80 Base assembly ...

Page 83: ...6 37 82 Control panel ...

Page 85: ...6 39 84 Fixed work table and turntable ...

Page 88: ...6 42 87 Use and maintenance manual DM 1215 Cylinder unit ...

Page 90: ...6 44 89 Use and maintenance manual DM 1215 Laser and lamp group ...

Page 92: ......

Page 132: ......

Page 136: ......