62

AUTO-LENSMETER

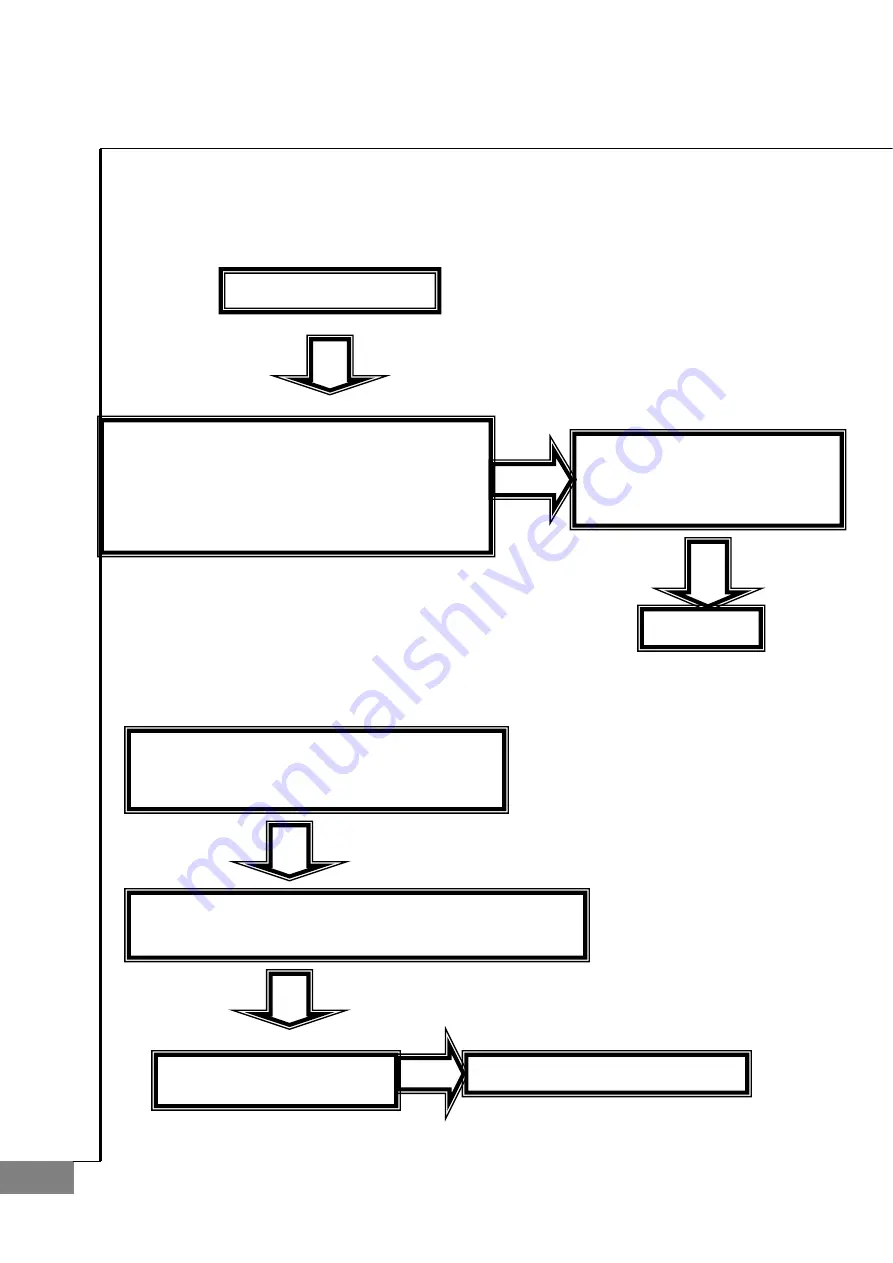

4.3. LCD

TEST

z

Measurement screen is not displayed

⋯

z

LCD is black-colored and screen is too dimmed

⋯

Check1. SMPS TEST

Y

E

S

Check1. LCD is bright but there is no character

or figure.

Check2. There are horizontal lines on LCD and

screen display is malfunctioned.

Check if J12 connector of LCD is

connected correctly to MAIN

BOARD.

YES

YES

Change LCD

Check1. Control by turning Bright Volume

right and left.

Check1. Check if J13 connector of KEYPAD PCB ASS

’

Y

is connected correctly.

Y

E

S

Y

E

S

Change KEYPAD PCB ASS

’

Y

NO

Change MAIN BOARD PCB ASS

’

Y

Summary of Contents for CLM-4000

Page 1: ......

Page 2: ...Auto Lensmeter CLM 4000 1 Service Manual Auto Lensmeter CLM 4000...

Page 5: ...4 AUTO LENSMETER 1 Introduction 1 1 Components List Figure 1 Components Names I...

Page 6: ...Auto Lensmeter CLM 4000 5 Figure 2 Components Names II Figure 3 Components Names III...

Page 26: ...Auto Lensmeter CLM 4000 25 Center Point A12 Angle of two points...

Page 29: ...28 AUTO LENSMETER 3 Repair Standard 3 1 Removing side cover assembly P I c t u r e 1 2 3 4 5...

Page 31: ...30 AUTO LENSMETER 3 2 Removing front cover Upper ass y P I c t u r e 1 2 3 4 5 6 7 8...

Page 33: ...32 AUTO LENSMETER 3 3 Removing Printer ass y P I c t u r e 1 2 3 4 5 6...

Page 35: ...34 AUTO LENSMETER 3 4 Removing PD assembly P I c t u r e 1 2 3 4 5 6 7 8 9 10...

Page 39: ...38 AUTO LENSMETER 3 5 Removing Body front cover Lower ass y P I c t u r e 1 2 3...

Page 41: ...40 AUTO LENSMETER 3 6 Removing UV assembly P I c t u r e 1 2 3 4 5...

Page 43: ...42 AUTO LENSMETER 3 7 Removing Movement assembly P I c t u r e 1 2...

Page 45: ...44 AUTO LENSMETER 3 7 1 Removing Movement Left Subassembly P I c t u r e...

Page 47: ...46 AUTO LENSMETER 3 7 2 Removing Movement Right Subassembly P I c t u r e...

Page 49: ...48 AUTO LENSMETER 3 8 Removing Gear assembly P I c t u r e 1 2 3 4 5 6 7 8...

Page 51: ...50 AUTO LENSMETER 3 9 Removing Main board assembly P I c t u r e 1 2...

Page 53: ...52 AUTO LENSMETER 3 10 Removing Back bone assembly P I c t u r e 1 2 3...

Page 57: ...56 AUTO LENSMETER 3 10 2 Removing CCD Camera assembly P I c t u r e 1 2 3 4 5 6 7...

Page 59: ...58 AUTO LENSMETER 3 11 Removing SMPS Assembly and Power cover P I c t u r e 1 2 3 4 5 6...