The simplest method to lift the cylinder is to allow the carburettor

with the inlet units and muffler to remain in place on the cylinder.

Dismantle according to this method as follows:

– Dismantle the three screws on the inlet units.

– Dismantle the lower screw on the muffler.

– Dismantle the four screws at the base of the cylinder.

New, run-in engine approximately 9 bar

Rectify below 7 bar

CYLINDER/PISTON

13

29

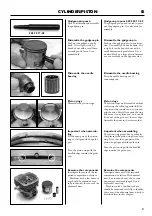

Compression test

The test indicates leakage from

the combustion chamber.

Close the decompression

valve or fit the sealing plug

503 55 22-01.

Cylinder

Dismantling

The service actions necessary determine the most appropriate method.

Splitting the machine at the vibration dampening element provides the best

view and accessibility. However, the cylinder can be lifted without this

splitting procedure.

It may be appropriate to secure the engine body in a vice to facilitate work.

Use soft jaw guards!

Compression test

The compression test indicates leakage

from the combustion chamber. If the

machine lacks engine power and is diffi-

cult to start this may be due to poor

compression.

Close the decompression valve or fit

the sealing plug 503 55 22-01 to eliminate

the decompression valve as the source of

the fault.

503 55 22-01

531 03 16-86

Compression tester

The compression test is performed using

the measurement instrument 531 03 16-86,

which is connected to the spark plug

hole. The valve below the gauge evacuates

the pressure.

Compression tester

Connect the compression tester

in the spark plug hole.

Compression test

– Run the engine warm for a few minutes.

– Unscrew the spark plug and con nect

the instrument.

– Make 5–6 attempts to start and read

the pressure on the gauge. Evacuate the

pressure and repeat the procedure a few

times. Note the average value for the

tests.

The average value for a new and run-in

engine is approximately 9 bar (130 psi).

Values less than 7 bar (100 psi) indicate

faults with on the cylinder, piston or

piston rings.

Compression test

– Run the engine warm.

– Connect the instrument.

– Make 5–6 attempts to start and

read the pressure. Evacuate the

pressure and repeat the procedure

a few times. Note the average

value for the tests.

Values less than 7 bar (100 psi)

indicate faults with on the cylin-

der, piston or piston rings.