7

52

Crankshaft and crankcase

Assembly

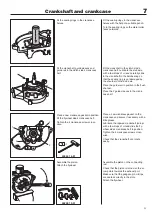

Mount the bearings in the crankcase

halves.

Inspect the small end of the connecting

rod.

Inspecting the crankshaft

Inspect the large end of the connecting

rod.

Check the crank bearing.

Assembly

Mount the bearings in the crankcase

halves.

Heat the crankcase halves to approx.

110°C using a hot air gun. Put the ball-

bearings in position.

Use a suitable punch and hammer, if

needed.

Inspect the small end of the connecting

rod.

If seizure marks or discolouration are

found in the bearing track the crankshaft

must be replaced.

Inspecting the

crankshaft

The crankshaft cannot be reconditio-

ned but must be replaced if it is worn or

damaged.

Inspect the large end of the connecting

rod. If seizure marks, discolouration on

the sides or damaged needle holders are

found the crankshaft must be replaced.

Check the crank bearing. The connecting

rod shall not have any radial play (up and

down).

It should, however, have axial play, in or-

der to ensure good lubrication of the crank

bearing among other things.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...