Setup mode

Chapter 4

OPERATION MANUAL

V2.2.0en/09.08.21//17.12

Unichiller® eo Desktop

49

Incorrect installation of the process sensor (Pt100)

MATERIAL DAMAGE CAUSED BY FAULTY TEMPERATURE CONTROL

Disruption of measured value recording due to static build-up.

The process sensor (Pt100) must have a screened supply cable.

If the sensor tube is metallic, take care to avoid ground loops.

The connection cable should not be unnecessarily long.

Make sure that the process sensor is properly attached at the measurement point and that

there is good thermal coupling

The sensor itself must have good insulation from the screen or the protective grounding (R > 20

MΩ).

4.2.4

Delta T limiter

The Delta T limiter is a part of the temperature control which protects the system or the process.

The Delta T limiter is given a limit value. The Delta T limiter then reacts when the limit value is

reached during heating or cooling.

The temperature control mode “Process (Cascade)” evaluates the temperature difference between

the flow temperature and the process temperature. The default setting of the limit value is 100 K. If

the limit value and the temperature sensor are set properly, the load limits, e.g. from a glass appa-

ratus, are not exceeded. As the limit value is approached, the cooling or heating capacity is adjusted.

The DeltaT limiter is

not

a safety device.

4.2.5

Monitoring the Pt100 temperature sensors

The Pt100 temperature sensors are constantly monitored for their electrical status. If the status

“Sensor faulty” occurs during temperature control, the temperature control process is stopped

immediately and a device message is displayed. This applies for all temperature sensors connected

within the temperature control unit.

4.2.6

Optimum control parameters for optimum temperature control

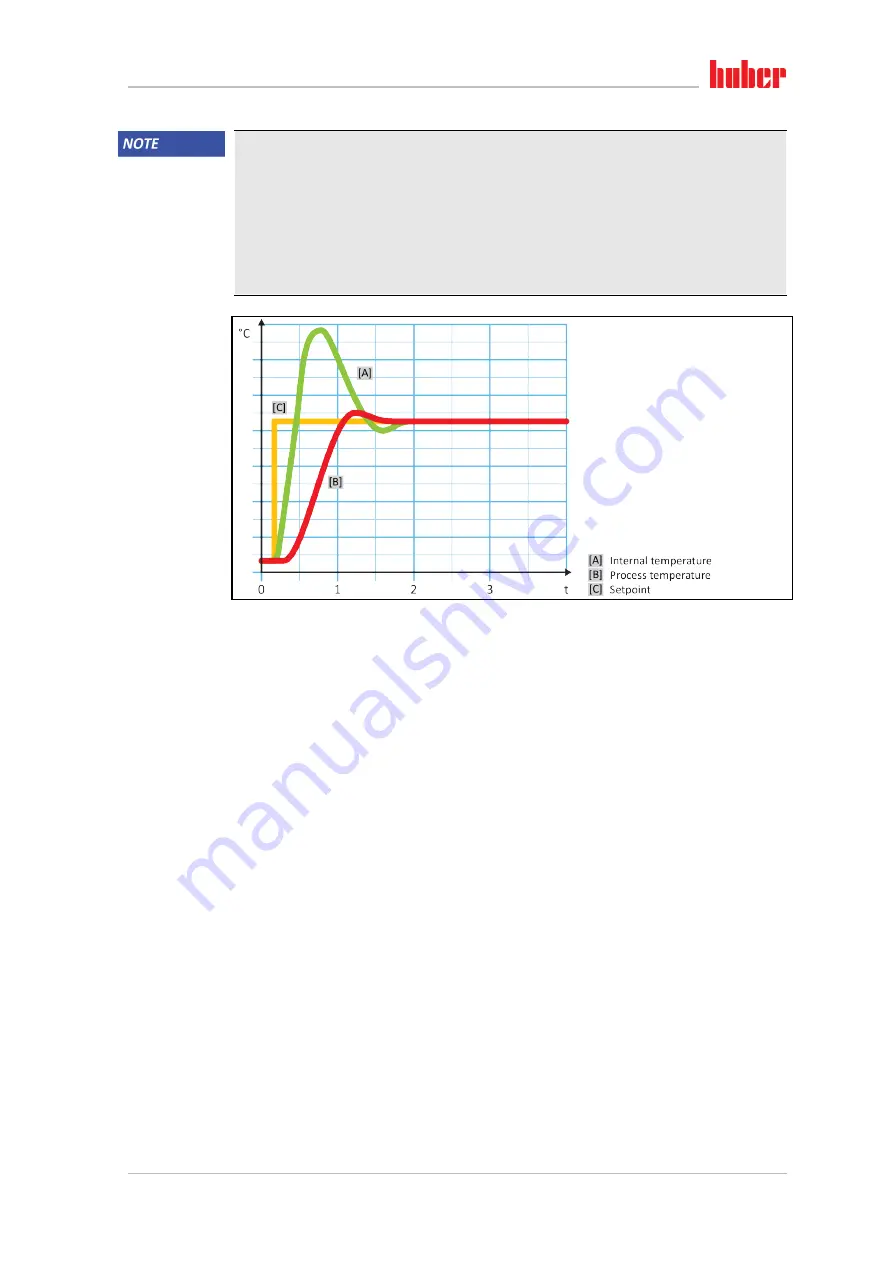

If the adjustment of the temperature does not correspond to the quality of the illustrations shown

above, you can adjust the control parameters. With Huber temperature control units, there are

various ways of finding the optimum control parameters. Depending on the facilities of the tempera-

ture control unit, you can choose the following processes:

▪

Use ex-factory parameters

(standard)

▪

Estimate Control Parameters

(only useful for bath thermostats with E-grade Basic and

internal control)

▪

Fast Identification

(from E-grade Exclusive)

▪

With Preliminary Test

(from E-grade Exclusive)

Representation of an

optimum process

temperature control