19

1. The stop valves for the gas pipe and liquid pipe on the indoor unit side are open, and those

on the outdoor unit side are closed.

2. (Leakage test with nitrogen) Inject nitrogen until the pressure reaches 3.0 MPa. Verify that

the pressure does not decrease after 24 hours under a stable ambient temperature. If any

leak is found after pressure preservation, check the pipe for leaks, especially the welding

points and stop valves.

3. (Vacuumizing) Replace the reducing valve and nitrogen cylinder with a vacuum pump.

Perform vacuumizing for at least 80 minutes and ensure that the final absolute pressure is

not greater than 60 Pa. When the final pressure does not decrease any more, continue to

vacuumize for 10 minutes. After vacuumizing is complete, close the vacuum pump and all

valves, and preserve the pressure for 10 minutes. Ensure that the absolute pressure does not

exceed 90 Pa. If the minimum reading of the pressure gauge is greater than 60 Pa, ensure

that the pointer stays at the smallest scale of the pressure gauge and preserve the pressure

for 1 hour. Then check that the pressure does not rise.

4. Open the stop valves for the gas pipe and liquid pipe of the outdoor unit.

9

Leakage Test with Nitrogen and Vacuumizing

•

After the outdoor unit stop valve is opened, the refrigerant in the outdoor unit flows to

the engineering pipe and indoor unit pipe. When performing other operations, be careful

to prevent refrigerant from spraying out.

•

After the vacuumization and before removing the rubber hose, ensure that there is

positive pressure inside the refrigerant pipe of the indoor unit. For detailed operations,

see step 1–4 in section "Commissioning Procedure".

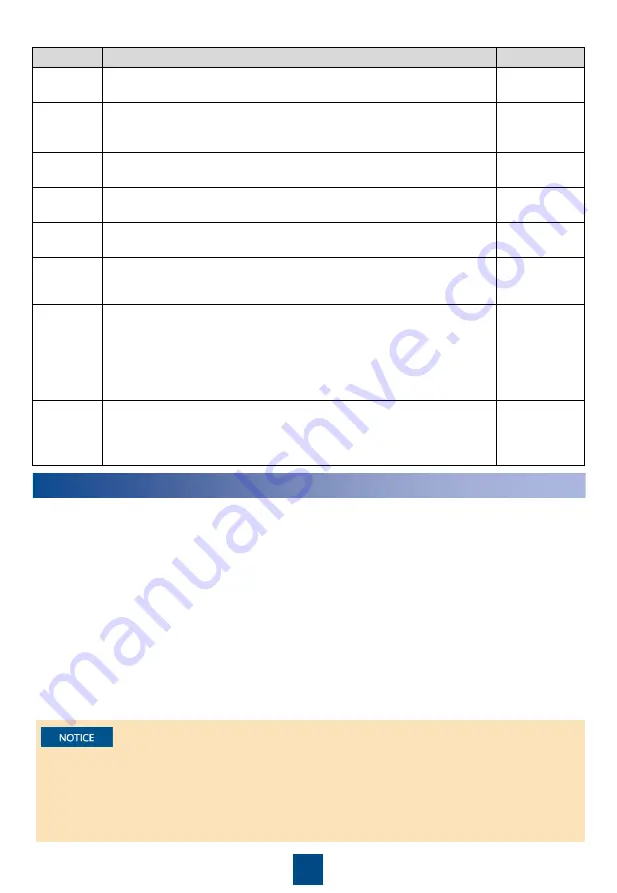

Item

Check That

Check Result

Indoor fan The fan is secured. The fan has no foreign matter inside.

□

Passed

□

Failed

Wet film

humidifier

(optional)

The water inlet solenoid valve, humidifier water pump, and wet film

are secured.

□

Passed

□

Failed

Humidifier

float

The humidifier float is secured. The fasteners for the humidifier float

are secured.

□

Passed

□

Failed

Liquid level

detector

The liquid level detector is secured. The fasteners for the liquid level

detector are secured. The low liquid level detector functions flexibly.

□

Passed

□

Failed

Return air

filter

The arrow direction of the return air filter is consistent with the return

air direction.

□

Passed

□

Failed

Outdoor

unit

The outdoor unit is secured. The outdoor unit air intake and exhaust

vents are not blocked. The outdoor unit installation meets

requirements.

□

Passed

□

Failed

Pipe

Pipe connectors are correct. The refrigerant pipe tilts and has supports.

The hose clamps and cable ties of the drainpipe are secured. The

refrigerant pipe and water pipe are wrapped with thermal insulation

foam. All pipes have been checked for leaks. Water pipe joints have

been sealed by sealant. The water inlet pipe and drainpipe also have

been checked for leaks. All pipes are not bent by a large angle.

□

Passed

□

Failed

Cable

The input voltage is within the range of rated voltage

±

10%, and the

input frequency is within the range of rated frequency

±

3 Hz. Cables

are not damaged. All cables, connectors, and bolts are secured. All

devices are correctly grounded.

□

Passed

□

Failed

Summary of Contents for NetCol5000-A011

Page 14: ...13 Downward pipe routing ...