Item

Measured Object

Specification

Analog signal

Measurement range

4 mA to 20 mA or 0 V to 5 V

Measurement precision

±1%

Relay output control

Control response time

< 1s

Dry contact output

capacity

Withstood voltage: 110 V DC, 125 V

AC; maximum load current: 1 A (30 V

DC)

Communication rate

RS-232 and RS-485

9600 bit/s

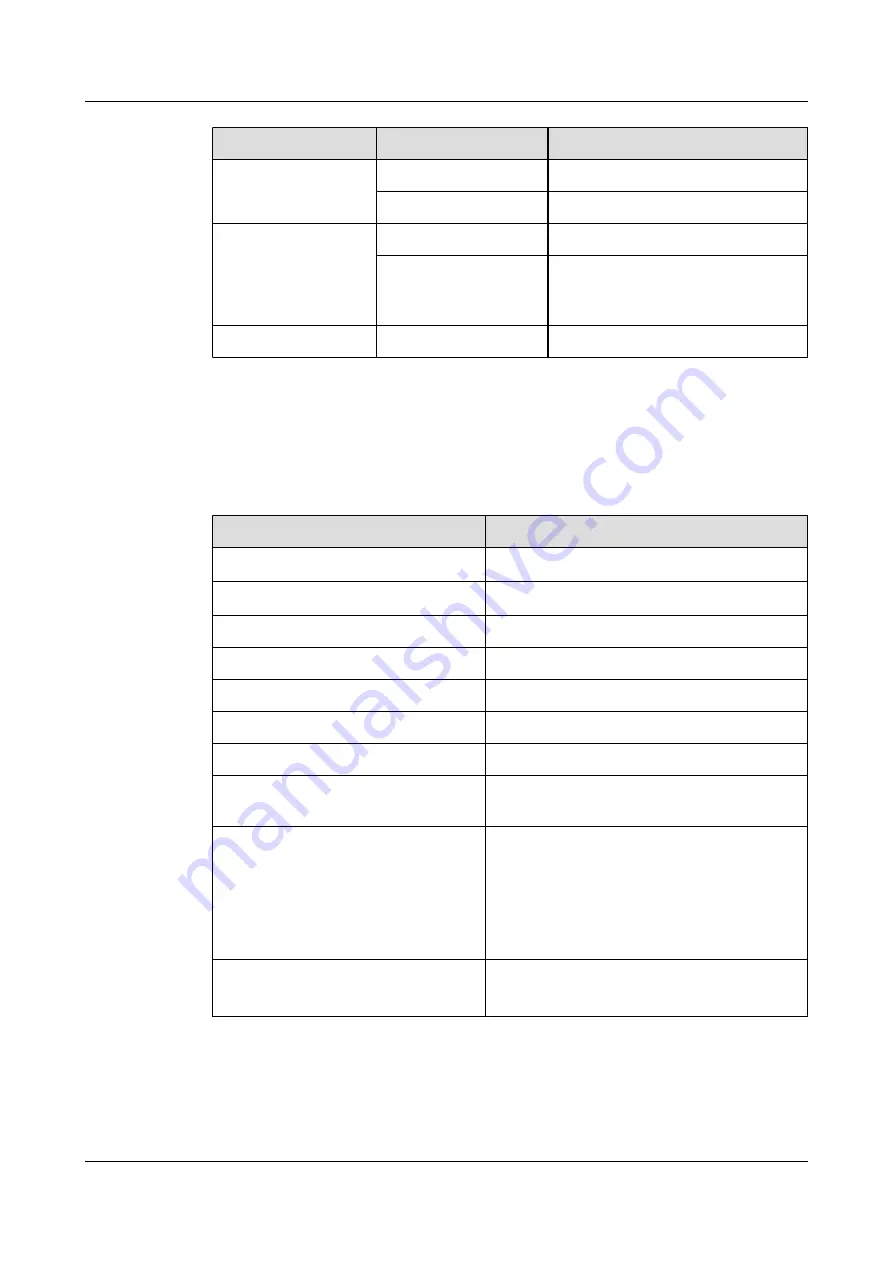

Performance specifications of the EMU

lists the performance specifications of the EMU.

Table 2-14

Performance specifications of the EMU

Item

Specification

Storage temperature

-40

o

C [-40

o

F] to +70

o

C [158

o

F] (no condensing)

Working temperature

-5

o

C [23

o

F] to 55

o

C [131

o

F]

Storage humidity

5% RH to 95% RH

Working humidity

10%RH to 90%RH

Working voltage type

DC

Rated working voltage

-48 V

Rated working current

0.2 A

Outline dimensions (including the

dimensions of mounting ear)

252 mm [9.92 in.] x 258 mm [10.16 in.] x 98 mm

[3.86 in.]

Outline dimensions (excluding the size of

mounting ear)

252 mm [9.92 in.] x 219 mm [8.62 in.] x 91 mm

[ 3.58 in.] (including the dimensions of the cord

end terminal)

252 mm [9.92 in.] x 209 mm [8.23 in.] x 91 mm

[ 3.58 in.] (excluding the dimensions of the cord

end terminal)

Net weight

Model A: 2.5 kg [5.51 lb]

Model A: 2.8 kg [6.17 lb]

2 Overview of the EMU

EMU

User Guide

2-20

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

Issue 13 (2009-12-30)