18

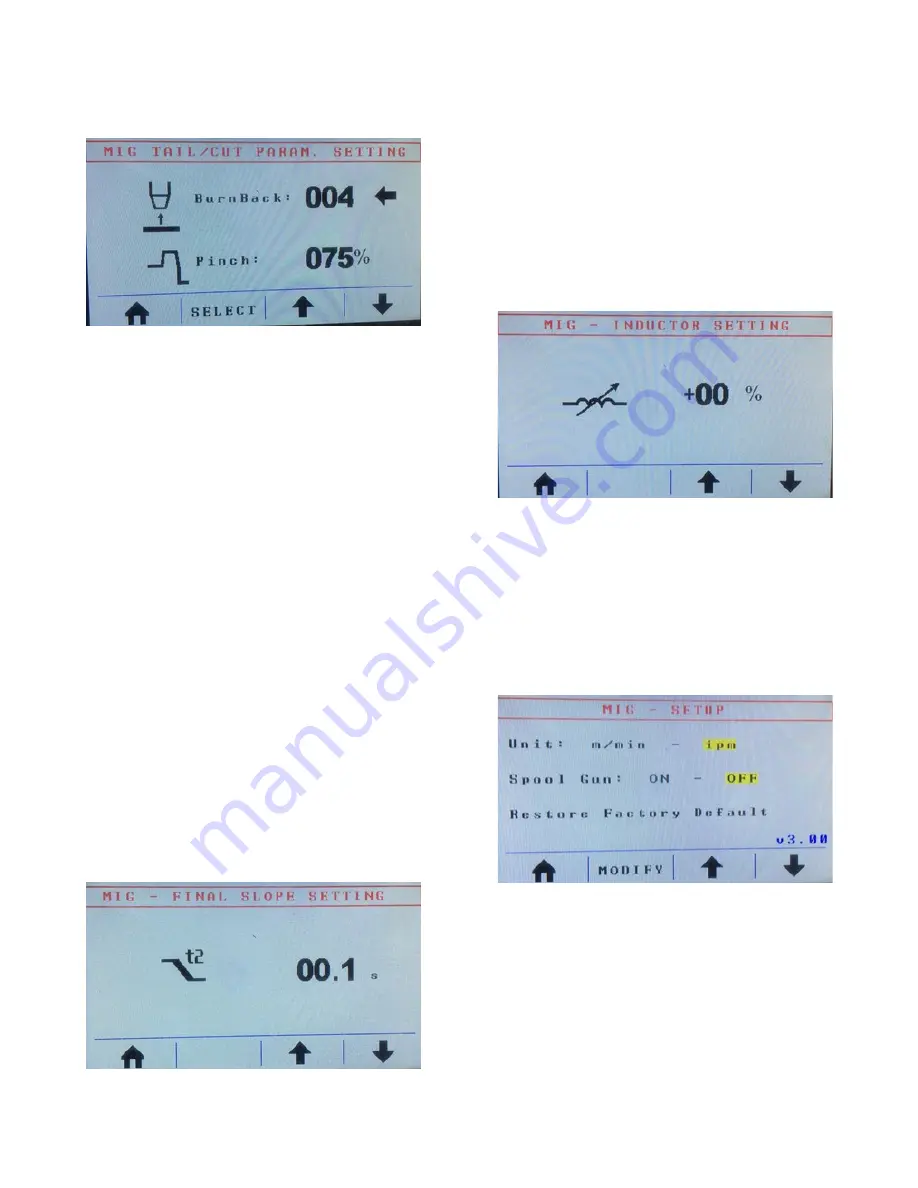

Fig. 16

To go to the next screen, press and release button

E

.

The new screen (

Fig. 16

) allows you to make

adjustments to what the wire does upon weld

completion. Burn back adjusts how long the wire

sticks out after you finish welding. A low number

allows the wire to stick out as it normally does on a

classic MIG welder, without any adjustments. The

higher the number, the shorter the stick out (

Attention:

High burn back numbers create the risk of burning the

wire back into the contact tip. We recommend starting

out with very low numbers

). Different wires react

differently. For example, aluminum reacts differently

than steel; when welding aluminum, set burn back to

004. The pinch function clips wire electrically. Right

before you finish the weld, the machine sends a burst

of current that shapes the end of the wire. Depending

on the setting, there might not be a ball on the end of

the wire that needs to be clipped off before re-striking

an arc. To set the pinch, push and release button

C

once, and then turn encoder

G

to the desired setting.

Different wire types need different settings. For

instance, flux-cored wire doesn’t need much pinch,

while aluminum wire tends to work well with 30% to

60% pinch, depending on the alloy and diameter (high

pinch rates, such as more than 75% pinch cause burn

backs near or into the tip, which causes damage to the

tip). Steel wire and 3/64” diameter 5554 aluminum

wire needs 100% pinch to get the desired result.

After adjusting the burn back and pinch, press and

release button

E

again to get to the next screen. This

screen (

Fig. 17

) allows you to adjust the slope down

setting for pulse welding. The slope down feature allows

you to fill the crater at the end of an aluminum weld or

allows you to neatly feather out a stainless steel weld.

On aluminum, set t2 between 3 and 5 seconds by turning

encoder

G

. After you release the trigger, the machine

still runs for the amount of time selected, but tapers

down automatically during the slope down time. The

tapering is visual in the arc and is also audible (the

frequency and the sound of the machine change). If no

slope down is desired, set t2 to 0.1 seconds.

Fig. 18

The slope down feature is only available in pulse

programs. Synergic, non-pulse programs have an option

to adjust inductance (

Fig. 18

). By turning encoder

G

,

you can adjust the inductance of the machine. Typically,

this feature is not available on transformer machines or

budget inverter machines. The inductance feature allows

you to set the arc characteristics from stiff/crisp to soft.

release button

C

(the little, left-pointing arrow will

move down from start speed to start time). Turning

encoder

G

now adjusts the start time.

Fig. 17

Fig. 19

You can access the final screen (

Fig. 19

) by pressing

and releasing button

E

once again. Options on the final

screen should not be adjusted by you unless previously

instructed by HTP America, Inc. technical service. In

this screen, the machine can be switched from Imperial

to Metric (which is preferred by many collision repair

shops). Also, if an optional spool gun is used on the

machine it needs to be activated here.

Summary of Contents for Pro Pulse 220 MTS

Page 5: ...5 Fig 1...

Page 13: ...13 Fig 3...

Page 26: ...26 Pro Pulse 220 MTS Wiring Diagram...