15

If you use a foot pedal, we recommend setting the

slope down time to 0.1 seconds.

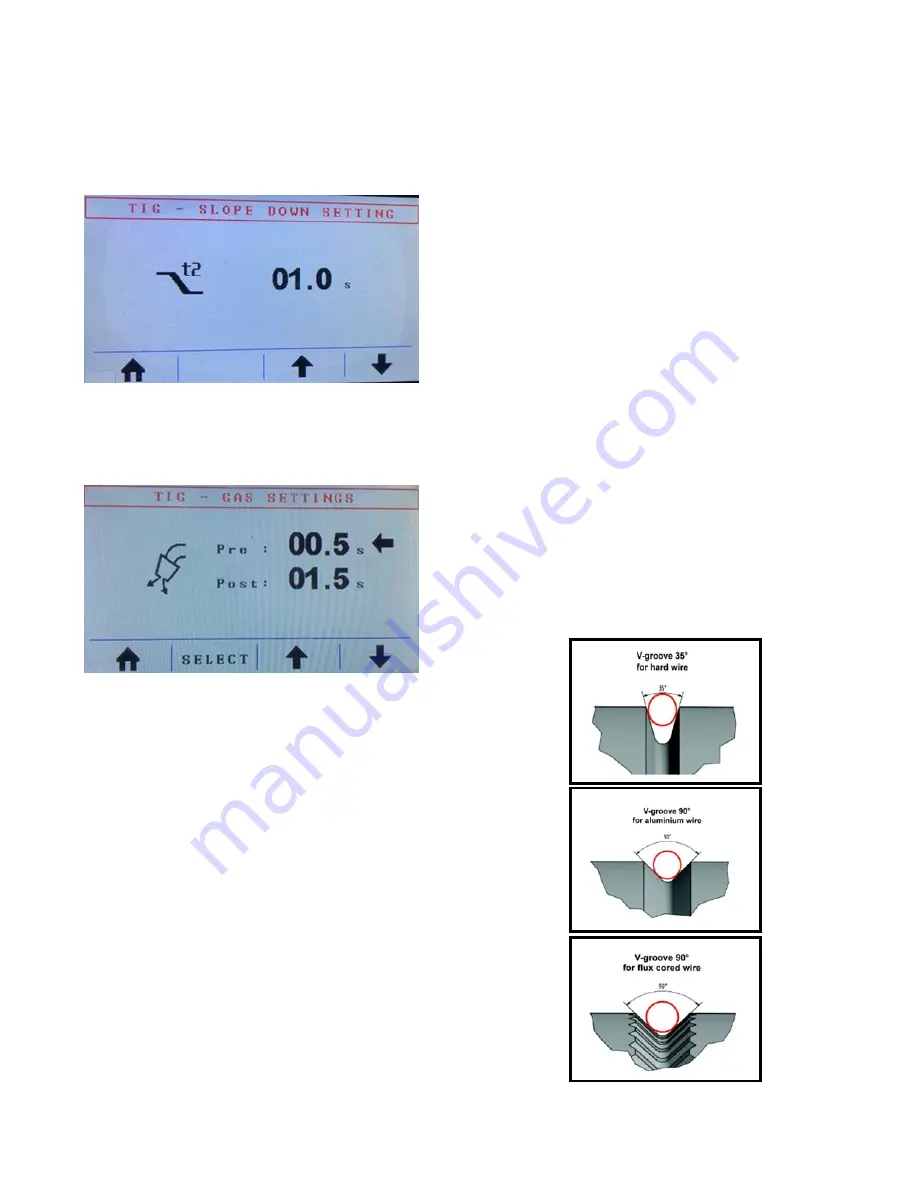

You can adjust the slope down time by turning encoder

G

until the display shows the desir ed dur ation (

Fig.

7

).

Fig. 7

To get to the next screen, press and release button

E

.

The next screen shows the gas flow options (

Fig. 8

).

Fig. 8

You can adjust the pre-flow gas setting by turning

encoder

G

. Pressing and releasing button

C

moves the

arrow from pre– to post-flow and turning encoder

G

now adjusts the post-flow gas setting.

We recommend a 5-10 second post-flow setting for

most TIG applications.

To Start the Arc

Touch the clean and freshly sharpened tungsten to the

clean metal of the work piece that you want to weld

and that you attached the ground clamp to. Now, press

and hold the torch switch, or depress the foot pedal

(just slightly), and lift the tungsten off the work piece

about 1/8”. The machine senses that the tungsten lifted

and initiates an arc. At this point, the weld can be

made. If you use a hand control or foot pedal, you can

vary the amperage during welding. When you finish, if

using a hand control, let go of the torch switch. The Pro

Pulse 220 MTS goes into slope down, and the arc

terminates by itself. If you use a foot pedal, gently lift

your foot off the pedal to extinguish the arc.

MIG Welding—General Information

MIG welding with the Pro Pulse 220 MTS can be done

three different ways: manual, synergic, and pulse. In

any case, the following things are critical to making

good welds:

Use the correct wire for the material being welded.

Use the correct gas, at the correct flow rate, for the

wire.

Use the drive roll with a groove that matches the

wire diameter chosen. There are different sizes and

shapes of drive rolls. For .023”, .024”, and .025”

diameter wire, use a drive roll marked 0.6;

for .030” wire, use a drive roll marked 0.8;

for .035” wire, use a drive roll marked 0.9 or 1.0;

for .045”, .047”, and 3/64” wire, use a drive roll

marked 1.2. (

Note: Drive rolls are reversible; there

are two different size grooves on the same drive

roll, and the marking has to face you

.) Also,

different materials require different drive roll

groove shapes. For instance, mild steel wire,

stainless steel wire, and silicon bronze wire

typically use a standard V shaped drive roll (

Fig.

9

). Softer aluminum wire uses a U shaped, or V90

degree, drive roll (

Fig. 10

). Flux-cored wire,

whether used with or without gas, and most hard-

faced wire requires the use of a knurled drive

roll—the little teeth provide extra traction on these

wires (

Fig. 11

).

Fig. 9

Fig. 10

Fig. 11

Summary of Contents for Pro Pulse 220 MTS

Page 5: ...5 Fig 1...

Page 13: ...13 Fig 3...

Page 26: ...26 Pro Pulse 220 MTS Wiring Diagram...