LP-719 Rev. 000 Rel. 000 Date 6.25.20

33

Friction Loss Equivalent in Piping and Fittings

Fittings or Piping

Equivalent Feet

2” or 3”

90 Degree Elbow*

5’

45 Degree Elbow

3’

Coupling

0’

Air Inlet Tee

0’

One Foot of Straight Pipe

1’

Concentric Kit

3’

V Series Vent Kit

1’

AL29-4C Vent Terminal

1’

Table 13 - Minimum - Maximum Vent Runs

Vent Sizing Example

If the exhaust vent run has two 90

o

elbows, 10 feet of straight pipe

and a concentric kit we will calculate:

Exhaust Vent Equivalent Length

= (2x5) + 10 + 3 =

23 feet

- Well

below the maximum of 100 ft in 2” pipe, or 150 ft in 3” pipe.

If the intake air pipe run has one 90

o

elbow, two 45

o

elbows, and 14

feet of straight pipe:

Intake Air Pipe Equivalent Length

= 5 + (2x3) + 14 =

25 feet

- Well

below the maximum of 100 ft in 2” pipe, or 150 ft in 3” pipe.

NOTE:

The intake air pipe and exhaust vent do not have to be of

equal length. There is no balancing requirement between intake and

exhaust.

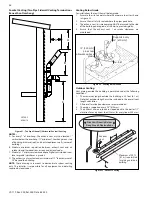

F. Tightening Boiler Collar to Exhaust Vent and Intake Pipe

Follow the steps to install exhaust vent pipe into the boiler vent

collar. See

Figure

21 for additional details.

NOTE:

Clean and dry the boiler connection.

DO NOT use primer or cement on the boiler connection.

Failure to install the boiler within the minimum and maximum vent

length requirements could result in improper product operation and

property damage, serious personal injury, or death.

E. Exhaust Vent and Intake Pipe Sizing

1. All models ship with 3” diameter vent pipe exhaust vent and intake

air pipe connections.

a. All 150 Models - Vent diameter may be DECREASED to 2”.

b. 199 / 199C Models must be vented in 3” diameter pipe.

c. Increasing the vent diameter of ANY model boiler IS NOT an

option.

2. The total length of the intake air pipe run must not exceed

one

hundred (100) feet in 2” pipe

, or

one hundred fifty (150) feet in 3”

pipe.

NOTE:

There is no minimum length for the intake air pipe run.

3.

The total length of the exhaust vent pipe run must not be less

than six (6) feet.

4.

The total length of the exhaust vent pipe run must not exceed

one hundred (100) feet in 2” pipe

, or

one hundred fifty (150) feet

in 3” pipe.

Minimum - Maximum Vent Run Lengths

Diameter

2”

3”

Intake Air Pipe Run

0 - 100 feet

0 - 150 feet

Exhaust Vent Run

6 - 100 feet

6 - 150 feet

Figure 21 - Correct Installation into the Appliance Collar

When venting with PVC, first install the included 5” length of 3”

CPVC into the boiler’s exhaust connection, then adapt to PVC

using approved CPVC to PVC transition cement. Installing PVC

pipe into the boiler’s exhaust connection is strictly prohibited -

the strain of the gear clamp combined with heat can deform PVC

over time and result in flue gas leakage causing property damage,

severe personal injury, or death.

WARNING

!

5. The equivalent length of elbows, tees, and other fittings are listed in

the Friction Loss Table below.

Table 14 - *Friction loss for long radius elbow is 1 foot less. NOTE: Consult

Polypropylene venting instructions for friction loss and pressure drop

equivalents.

WARNING

!

When preparing pipe for installation:

•

Ensure cuts are square.

•

Bevel cut edges by 1/16” - 1/8”. Deburr the pipe.

•

Lubricate the gasket.

1. Push the length of pipe into the connection until it touches the

bottom of the fitting.

2. Tighten the clamps using a screwdriver.

3. Ensure the pipe is secure before continuing installation.

NOTE:

To install intake pipe, follow the steps for installing exhaust

vent pipe.

G. Exhaust Vent and Intake Pipe Installation

All joints of positive pressure vent systems must be sealed

completely to prevent leakage of flue products into the living

space. Failure to do so could result in property damage, serious

injury, or death.

WARNING

!

1. Use only solid PVC, CPVC, or stainless steel pipe or a

Polypropylene vent system approved for use with Category IV

appliances.

ABS pipe material may be used on air inlet piping

only

.

2. Remove all burrs and debris from joints and fittings.

3. When using PVC or CPVC pipe, all joints must be properly

cleaned, primed, and cemented. Use only cement and primer

approved for use with the pipe material. Cement must conform

to ASTM D2564 for PVC and ASTM F493 for CPVC pipe.

NOTE:

DO NOT CEMENT POLYPROPYLENE PIPE.

4. Ensure the vent is located where it will not be exposed to

prevailing winds.

5. In all roof venting applications, exhaust discharge must point

away from the pitch of the roof.

6. If the exhaust vent is to be terminated in a walled off area

Figure 22 - Air Intake Pipe Installed (Left Side Installation

Demonstrated)

Reducing Vent Diameter - 150 Models ONLY!

In order to use 2” pipe, it is required to reduce pipe size in a vertical

length of pipe with a 3” x 2” reducing coupling (not included).

NOTE:

A reducing coupling MUST BE USED when transitioning

from 3” to 2” vent pipe. DO NOT use reducing bushings.