Overview of Server Installation

Accessing the Redundant Power Supply Bay

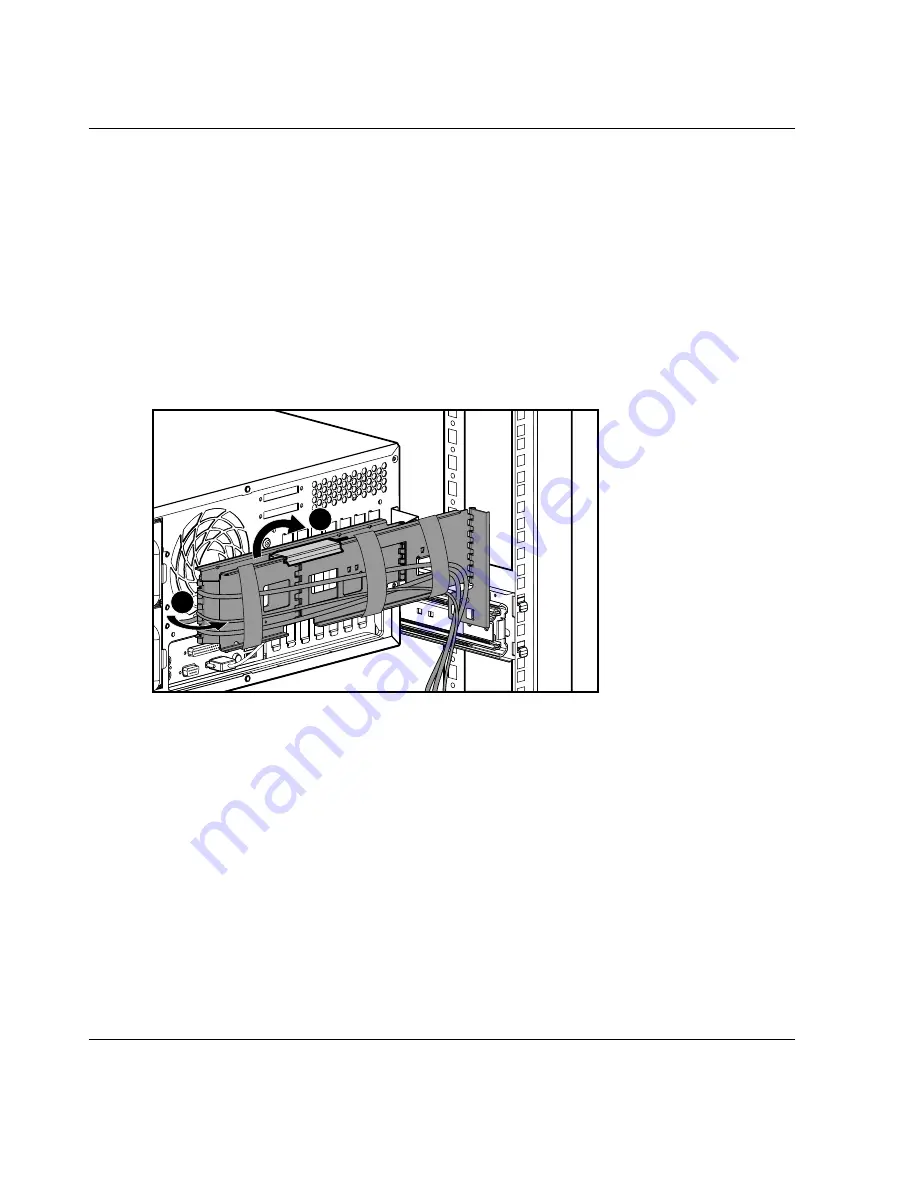

The cable management arm comes with a center joint to allow easy access to the

power supply bays without having to remove the arm.

To service the power supply bays:

1.

Lift up the center joint locking bracket located near the center of the outside

cable management arm piece (1).

2.

Swing the cable management arm back away from the server chassis (2).

1

2

Figure 2-19: Swinging the Cable Management Arm away

from the chassis

3.

After completing the desired service function, return the cable management arm

to its locked position by reversing steps 1 and 2.

Powering Up the Server

Power up the server after the peripheral and power cords are connected to the server.

2-28

HP ProLiant ML350 Generation 3 Server Setup and Installation Guide

HP CONFIDENTIAL

Writer: Richard O. Heath File Name: c-ch2 Overview of Server Installation.doc

Codename: Steel Venom Part Number: 316354-001 Last Saved On: 12/6/02 2:56 PM