24. If the Clean/Rinse Outlet Valve is installed, position it to discharge out toward the brine discharge connector.

25. One final time, fill the Rinse/Clean Solution Container with non-chlorinated product water.

26. Start the system. The rinse water rinses the entire system and discharge to waste.

27. Just prior to depleting the rinse water from the Rinse/Clean Solution Container, stop the system by pressing

the “START/STOP” switch once to initiate the Automated Freshwater Flush Cycle every 7 days. Press the

“START/STOP” switch twice to abort the Automated Freshwater Flush Cycle.

28. Reconfigure the system for normal operation:

a) Reconnect the Sea Strainer outlet line or reposition the Inlet Rinse/Clean Valve to normal operation position.

b) Remove the Product Relief Tube Kit.

c) Reconnect the High-Pressure Hose.

The system may now be operated or left unattended for up to 4 to 8 weeks, refer to the short-term storage

procedures. If the system will be stored without use for longer than 8 weeks, refer to the long-term storage procedures

to winterize the system. If the system will be stored in freezing temperatures refer to short-term storage procedures

or long-term storage procedures, as appropriate, to winterize the system.

Seafari QUEST 200-600

48

Summary of Contents for Seafari Quest Compact 200

Page 2: ......

Page 3: ...Seafari QUEST 200 600 Owner s Manual Horizon Reverse Osmosis Manual PN B651100001...

Page 4: ......

Page 8: ......

Page 16: ......

Page 22: ......

Page 52: ......

Page 60: ......

Page 62: ...2 12 4 12 8 10 7 3 1 6 5 9 12 11 4 Seafari QUEST 200 600 60...

Page 68: ...11 13 6 14 16 1 4 5 9 3 10 8 2 7 8 15 12 Seafari QUEST 200 600 66...

Page 70: ...9 3 5 4 1 10 8 16 14 11 2 15 12 13 7 8 6 Seafari QUEST 200 600 68...

Page 72: ...11 13 6 14 16 1 4 5 9 3 10 8 2 7 8 15 12 Seafari QUEST 200 600 70...

Page 74: ...9 3 5 4 1 10 8 16 14 11 2 15 12 13 7 8 6 Seafari QUEST 200 600 72...

Page 76: ...13 15 8 16 9 1 6 7 4 12 11 3 10 11 20 14 5 2 21 19 17 18 Seafari QUEST 200 600 74...

Page 78: ...4 7 6 1 12 11 9 16 13 3 20 14 15 10 11 8 5 2 18 21 19 17 21 Seafari QUEST 200 600 76...

Page 80: ...13 15 8 16 9 1 6 7 4 12 11 3 10 11 20 14 5 2 21 19 17 18 Seafari QUEST 200 600 78...

Page 82: ...4 7 6 1 12 11 9 16 13 3 20 14 15 10 11 8 5 2 18 21 19 17 21 Seafari QUEST 200 600 80...

Page 85: ...9 9 6 3 8 7 1 5 1 4 9 6 2 11 12 10 12 10 1 83 Exploded Parts View...

Page 89: ...19 10 13 20 4 15 5 3 8 6 14 15 11 9 7 13 10 20 2 19 18 22 21 12 16 17 1 87 Exploded Parts View...

Page 91: ...5 6 2 3 2 6 7 9 9 8 1 10 5 89 Exploded Parts View...

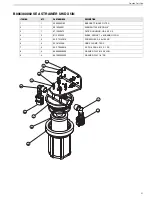

Page 101: ...12 8 9 2 10 13 1 3 5 4 14 11 6 15 7 99 Exploded Parts View...

Page 104: ...8 15 14 13 6 2 1 16 5 10 3 6 6 8 4 12 7 15 11 9 Seafari QUEST 200 600 102...

Page 114: ......

Page 115: ......