l1/Z” A P P R X (13mm)

MOTOR

PULLEY

1938

Fig. 2.

BELT ADJUSTMENT

Hand pressure should depress the belt about 1/2 inch.

See Figure 2. The belt should be tight enough so that no

slipping occurs. A belt that is unnecessarily tight can

cause excessive wear.

Adjust belt tension by loosening the motor hold-

down bolts, moving the motor until tension is correct.

Then retighten the bolts. Make certain that belts and

pulleys are aligned properly. If a belt becomes worn or

frayed, replace it.

PRESSURES

When making weekly maintenance checks, verify that

the tank pressure is in the 70 to 90 psi (480 to 620 kPa)

range. Also make certain that the PRV pressure for

each

unit is at the proper setting.

COMPRESSOR OPERATION

As part of the weekly operational check, confirm that

the compressor does

have

an “off" period and is not

running continuously. Note that on WP240 Compressors,

the manual alternation system should be switched over

to confirm the start-up and off cycle of both pumps.

Every three months, the cut-in pressure, pump up

time, cut-out pressure, and off time should be measured

under normal operating conditions. It should be below

50 percent operation, that is, it should have more off

time than on time. It should operate approximately

from 70 to 90 psi (480 to 620 kPa) on the 1/4 to 5 HP

units and from 60 to 100 psi (415 to 690 kPa) on the

7-l/2 to 20 HP units. Note that on the WP240 units,

the

pumps should be switched and rechecked (switching is

automatic on some units).

A good maintenance practice is to keep

these

figures

for practice. If possible, attach a card with the figures to

the device. Decreasing off periods with no change in the

pressure range indicate an increase in air consumption,

Pump up times will increase also. This can be caused by

added devices or leaks. Increasing pump up time with

no

change in the pressure range or off time indicates wear in

the compressor and may warrant closer observation, This

is usually followed by an increase in oil consumption.

If there is suspicion of wear, the dead ended pump

up time (pumping up the tank with the system shut off)

should be checked against the value given in the data

table. If it differs from the data table by more than 10

percent, then an analysis of the cause should be made

and the situation corrected. Refer to the WP240 Wiring

Diagrams and the WP250 Wiring Diagrams for operation

unique to these models.

TROUBLESHOOTING

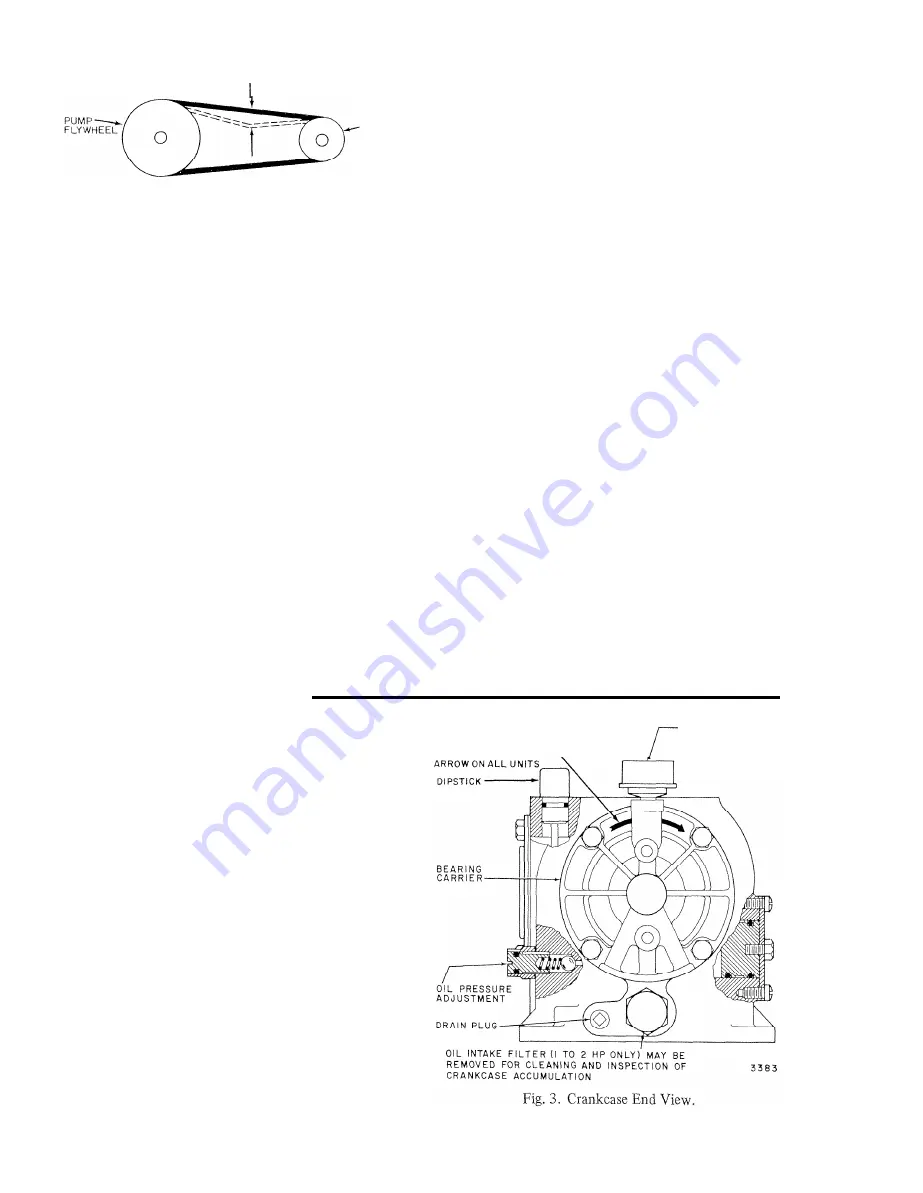

ROTATION OF FLYWHEEL

MUST BE IN THE SAME

DIRECTION AS THE

\

OIL

PRESSURE

GAGE

WRONG OIL PRESSURE

Normal oil pressure for these compressors is from 10

to 20 psi (70 to 140 kPa). There should be no pressure

during the “Off” cycle. Check the oil level and clean the

oil intake filter before adjusting pressure. The oil pres-

sure is regulated by a spring loaded ball that is mounted

in the bearing carrier or in the crankcase near the bearing

carrier. See Figure 3, This is on the same side as the dip-

stick. The spring pressure is controlled by an adjusting

screw. Turning the screw inward will increase the pres-

sure.

Be sure to loosen the adjustment lock nut before

making any adjustment. Turn the adjustment screw

slowly until the oil gauge registers approximately 1.5 psi

(105 kPa). After the adjustment has been made, tighten

the adjustment screw lock nut.

75-7131

Summary of Contents for WP230A-M

Page 19: ......