Air Supply Equipment

132

customer.honeywell.com

70-6925

The refrigerant dryer uses a non cycling operation with a hot

gas bypass control on the refrigerant flow to provide a constant

dew point of approximately 35F at the tank pressure. The

refrigeration circuit is hermetically sealed to prevent loss of

refrigerant and lubricant and to protect against dirt.

The heat exchanger reduces the temperature of the

compressed air passing through it. A separator/filter condenses

both water and oil from the air and ejects the condensate

through a drain. A temperature-sensing element controls the

operation of the refrigeration system to maintain the

temperature in the exchanger.

With a dew point of 35F and an average compressor tank

pressure of 80 psi, air is dried to a dew point of 12F at 20 psi.

Under severe winter conditions and where piping and devices

are exposed to outside temperatures, the 12F dew point may

not be low enough.

DESICCANT DRYING

A desiccant is a chemical that removes moisture from air. A

desiccant dryer is installed between the compressor and the

PRV. Dew points below -100F are possible with a desiccant

dryer. The desiccant requires about one-third of the process air

to regenerate itself, or it may be heated. To regenerate,

desiccant dryers may require a larger compressor to produce

the needed airflow to supply the control system and the dryer.

It may be necessary to install a desiccant dryer after the

refrigerant dryer in applications where the 12F dew point at 20

psi mainline pressure does not prevent condensation in air lines

(e.g., a roof-top unit exposed to severe winters).

The desiccant dryer most applicable to control systems uses

the adsorbent principle of operation in which porous materials

attract water vapor. The water vapor is condensed and held as

a liquid in the pores of the material. The drying action continues

until the desiccant is saturated. The desiccant is regenerated by

removing the moisture from the pores of the desiccant material.

The most common adsorbent desiccant material is silica gel,

which adsorbs over 40 percent of its own weight in water and is

totally inert. Another type of adsorbent desiccant is the

molecular sieve.

A desiccant is regenerated either by heating the desiccant

material and removing the resulting water vapor from the

desiccant chamber or by flushing the desiccant chamber with

air at a lower vapor pressure for heatless regeneration. To

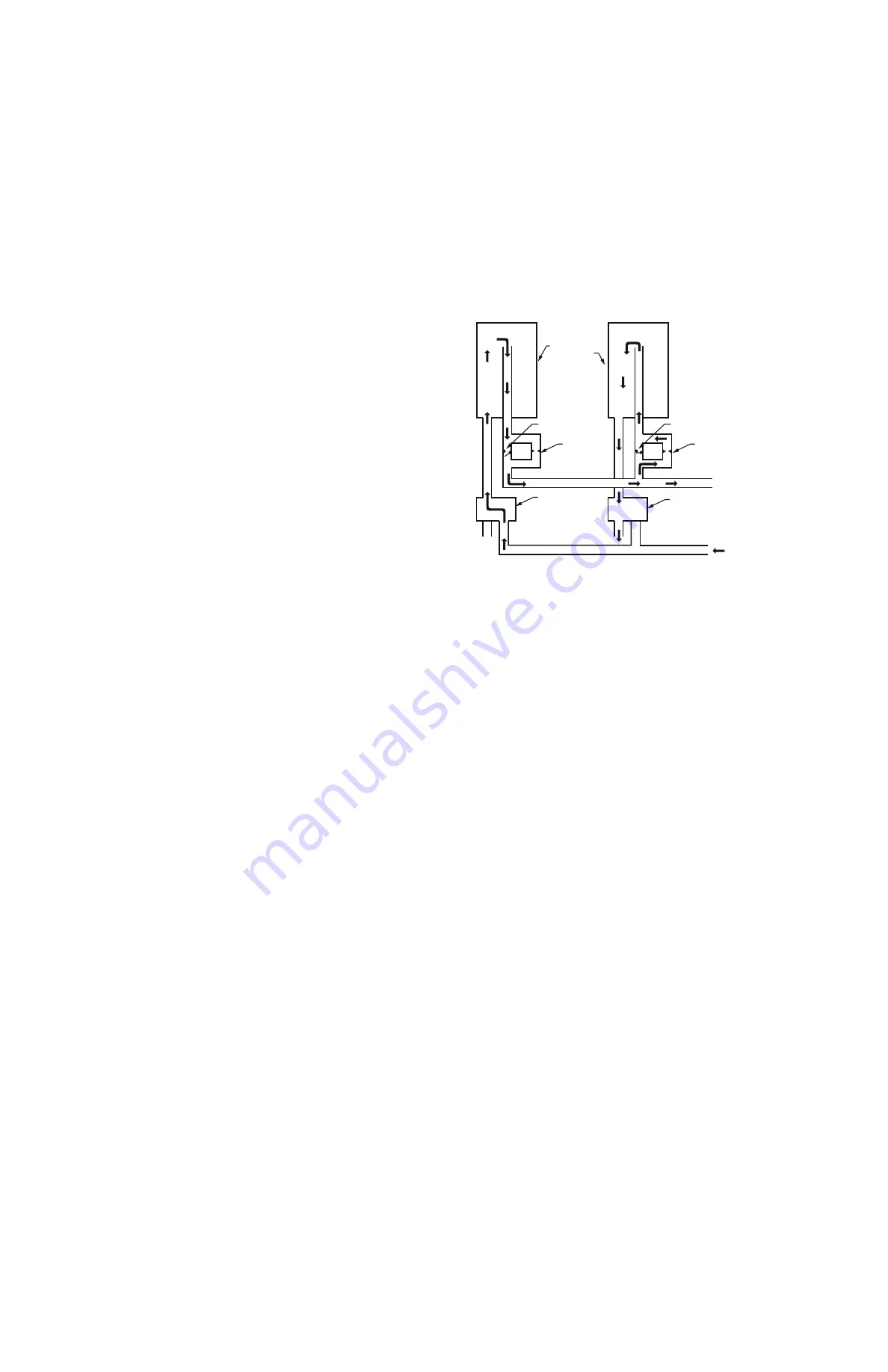

provide a continuous supply of dry air, a desiccant dryer has

two desiccant chambers (Fig. 15). While one chamber is being

regenerated, the other supplies dry air to the system. The

cycling is accomplished by two solenoid valves and an electric

timer. During one cycle, air passes from the compressor into the

left desiccant chamber (A). The air is dried, passes through the

check valve (B), and flows out to the PRV in the control system.

Fig. 15. Typical Heatless Desiccant

Dryer Airflow Diagram.

Simultaneously, some of the dried air passes through the orifice

(G) to the right desiccant chamber (E). The air is dry and the

desiccant chamber is open to the atmosphere, which reduces

the chamber pressure to near atmospheric pressure. Reducing

the air pressure lowers the vapor pressure of the air below that

of the desiccant, which allows the moisture to transfer from the

desiccant to the air. The timer controls the cycle, which lasts

approximately 30 minutes.

During the cycle, the desiccant in the left chamber (A) becomes

saturated, and the desiccant in the right chamber (E) becomes

dry. The timer then reverses the flow by switching both of the

solenoid valves (D and H). The desiccant in the right chamber

(E) then becomes the drying agent connected to the

compressor while the desiccant in the left chamber (A) is dried.

The process provides dry air to the control system continually

and requires no heat to drive moisture from the desiccant. A

fine filter should be used after the desiccant dryer to filter out

any desiccant discharged into the air supply.

A heated dryer also has two chambers where one is heat-

regenerated while the other dries the compresses air.

Periodically, the regenerating and drying action is switched.

Pressure Reducing Valve Station

The pressure reducing valve station is typically furnished with

an air filter. The filter, high-pressure gage, high pressure relief

valve, pressure reducing valve (PRV), and low-pressure gage

are usually located together at one point in the system and may

be mounted directly on the compressor. The most important

elements are the air filter and the PRV.

C1889

DESICCANT

CHAMBERS

CHECK

VALVE

CHECK

VALVE

ORIFICE

ORIFICE

SOLENOID

A

B

C

D

DRY AIR OUT

H

G

F

E

AIR FROM COMPRESSOR

SOLENOID

Summary of Contents for VP525C

Page 58: ...50 customer honeywell com 70 6925 ...

Page 120: ...112 customer honeywell com 70 6925 ...