60-2035—9

6

RA890G

OPERATION AND CHECKOUT

IMPORTANT: If limit control opens, ignition and fuel

valves are de-energized, but safety switch lockout will

not occur. When normal conditions are restored and

the limit closes, the RA890G recycles.

CHECKOUT REQUIRED

Before the installation is complete, satisfactorily com-

plete all checkout tests indicated below. Repeat these tests

after any adjustments are made to the system.

Flame Current Check (all installations).

Pilot Turndown Test (all installations that required proof

of pilot before main fuel valve is opened).

Ignition Spark Response Test (all installations).

Safe Shutdown Checks—Flame failure, power failure,

limit action (all installations).

FLAME CURRENT CHECK

The Flame Current Check is the best indicator of proper

flame detector application. Perform the check at the time of

installation, at any time service is done on the system, and at

least once a month (or more often) while the system is in

operation. This prevents shutdowns due to poor flame signal.

Use a W136A Microammeter, or equivalent, and read the

flame signal while the burner is running. Insert a 196146 Test

Cable, wired color-to-color to the W136A leadwires, into the

test jack on the RA890G. See Fig. 6.

When reading the flame current, assure that the following

criteria are met:

1. The flame current is steady; meter does not vary more

than a needle width.

2. The flame current is at least 1.5 microamperes for an

ultraviolet type detector such as used with the RA890G.

If a satisfactory reading is not obtained, check the power

source for the proper line voltage, and the flame size and the

detector for proper sensing.

Directions for obtaining a steady current reading are

included in the instructions packed with the C7027, C7035

or C7044 Ultraviolet Flame Detector.

NOTE: Flame current cannot be measured by putting a

microammeter in the F lead.

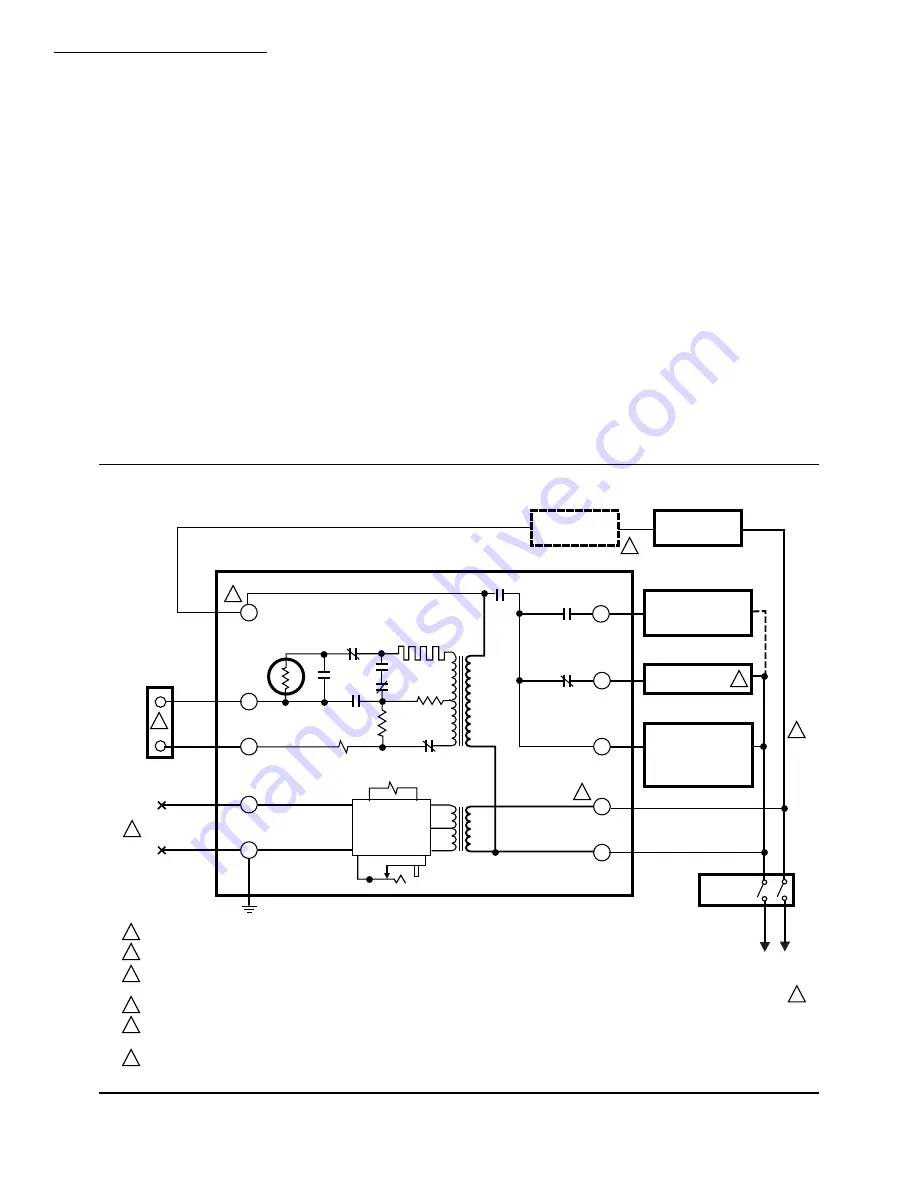

Fig. 5—Internal Schematic of RA890G (Typical External Connections Included).

L1

(HOT)

L2

2

5

1

2

6

4

3

3

1

2

3

4

5

6

PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

RA890G TERMINALS 1 AND 6 MUST BE POWERED.

MAY USE LINE OR LOW VOLTAGE CONTROLLER. IF LINE VOLTAGE CONTROLLER IS USED, CONNECT IT BETWEEN THE LIMIT

CONTROLLER NAD TERMINAL 6. JUMPER T-T.

FOR INTERMITTENT IGNITION CONNECT TO TERMINAL 3.

MINIPEEPER DETECTORS ARE POLARITY SENSITIVE—BLUE LEAD MUST BE CONNECTED TO THE F TERMINAL;

WHITE LEAD CONNECTED TO THE G TERMINAL.

ALL WIRING MUST BE NEC CLASS 1.

LOW VOLTAGE

CONTROLLER

TO FLAME

DETECTOR

THERMISTOR

1K

(LOAD RELAY)

2K (FLAME RELAY)

ELECTRONIC

AMPLIFIER

NETWORK

LINE VOLTAGE

CONTROLLER

LIMIT

CONTROLLER

MAIN GAS VALVE

OR SECOND STAGE

OIL VALVE (IF USED)

INTERRUPTED

IGNITION

PILOT GAS VALVE,

OR BURNER MOTOR

AND DELAYED OIL

VALVE; INTERMITENT

IGNITION

MASTER

SWITCH

POWER

SUPPLY

TEST

JACK

TR2

SAFETY

SWITCH

2K3

1K2

2K4

SAFETY

SWITCH

HEATER

1K1

TR1

2K2

2K1

M8721

5

4

3

1

2

G

F

T

T

6

BLUE

WHITE

1K3

1K4

RA890G

Summary of Contents for RA890G

Page 11: ...11 60 2035 9 ...