L7124U UNIVERSAL OIL ELECTRONIC AQUASTAT® CONTROLLER

69-1232—2

2

INSTALLATION

When Installing this Product...

1.

Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2.

Check the ratings given in the instructions and on

the product to make sure the product is suitable for

your application.

3.

The installer must be a trained, experienced

service technician.

4.

After installation is complete, check out product

operation as provided in these instructions.

WARNING

Electrical Shock Hazard.

Can cause serious injury or death.

Disconnect power supply before beginning

installation to prevent electrical shock or

equipment damage.

Mounting

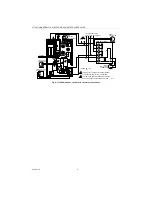

The L7124U has a case that can be converted for either

horizontal or vertical mounting. See Fig. 1.

IMPORTANT

Immersion well must fit sensing element and

sensor bulb must rest against bottom of well.

New Installation

Order well assemblies for the L7124U separately; see

form 68-0040, Wells and Fittings for Temperature

Controllers. Boilers usually have tappings that allow

the well to be mounted horizontally so boiler water of

average temperature can circulate freely.

1.

Turn off all power and drain the boiler.

2.

If no tapping is provided, prepare properly sized

and threaded tapping near the top of the boiler.

3.

Sparingly coat the well threads with pipe dope.

Fig. 1. Case designed for vertical

or horizontal mounting.

NOTE: Do not attempt to tighten by using the case as a

handle.

4.

Install the well in the boiler tapping and tighten

securely.

5.

Refill boiler and check for water leakage.

6.

Loosen but do not remove the clamp screw on the

L7124U case.

7.

Insert the sensor element into the well until it

bottoms. (If necessary, slightly bend the tube inside

the case to hold the sensor against the bottom of

the well.)

NOTE: Some models have an adjustable wire length to

3 in. (76 mm). For these models, pull out extra

wire length from inside the case, if needed.

8.

Fit the case into the well so the clamp on the case

slides over the flange on the well.

9.

Securely tighten the clamp screw.

IMPORTANT

Best thermal response is obtained with a well

that snugly fits the sensor. Insert the sensor

until it rests against the bottom of the well. use

a well of correct length and bend the wiring, if

necessary, to hold the bulb against the bottom

of the well.

If the well is not a snug fit on the sensor, use

the heat-conductive compound (furnished with

TRADELINE models) as follows: Fold the

plastic bag of compound lengthwise and twist it

gently. Then snip off end of bag and work the

open end of the bag all the way into the well.

Slowly pull out the bag while squeezing it firmly

to distribute compound evenly in the well. Bend

the wiring, if necessary, to hold the sensor

against the bottom of the well and to hold outer

end of the sensor in firm contact with the side of

the well. See Fig. 2. Wipe excess compound

from the outer end of the well.

Replacement Installation

Turn off all power and remove the old control. Refer

to the cover insert of the old control to identify and tag

each external lead as it is disconnected. If the old well is

unsuitable for the new installation, remove it and proceed

with instructions for new installation. If the old well is

suitable, use it and an immersion well adapter (ordered

separately) for the installation. (The well clamp may fit

directly over the flange of the existing well spud and

using the adapter may not be necessary.) The adapter

has a flange at the wide end that fits into the well clamp

and is slotted lengthwise to accommodate the sensor

wire.

1.

Loosen but do not remove the well clamp screw on

the side of the control case.

2.

Pull out the wire until the sensor bottoms in the

well. Place adapter, if used, around the sensor wire

so it fits into the slot. See Fig. 2.

3.

Make sure the wide end of the adapter fits into the

hole in the case. Position immersion well clamp

snugly over the flange of the adapter and tighten

the clamp screw.

4.

Insert the sensor into the well as shown in Fig. 2.

(Distribute the heat-conductive compound in the

tube prior to bulb insertion.)

5.

Securely tighten the setscrew against the adapter.

BRACKET POSITION FOR

VERTICAL MOUNTING

BRACKET POSITION FOR

HORIZONTAL MOUNTING

M8890

Summary of Contents for L7124U

Page 7: ...7 69 1232 2 ...