INTELLIDOX DOCKING MODULE USER MANUAL || DETECTOR OPERATIONS

HONEYWELL

PAGE 57 OF 119

Ensuring proper operation of the IntelliDoX BW Clip4 module

After performing a bump test or calibration, remove the detector from the IntelliDoX

docking module to allow any residual gas to clear.

Leaving the detector in the docking module may cause it to fail the calibration. If a detector

is bump tested and then a calibration is performed without removing it from the docking

module, residual gas may cause the calibration to fail.

Calibrating a Detector

You may use Safety Suite Device Configurator software to configure a detector to

automatically perform calibration on insertion if the sensor calibration is overdue. When a

compatible detector is inserted into the module and the calibration is overdue, then

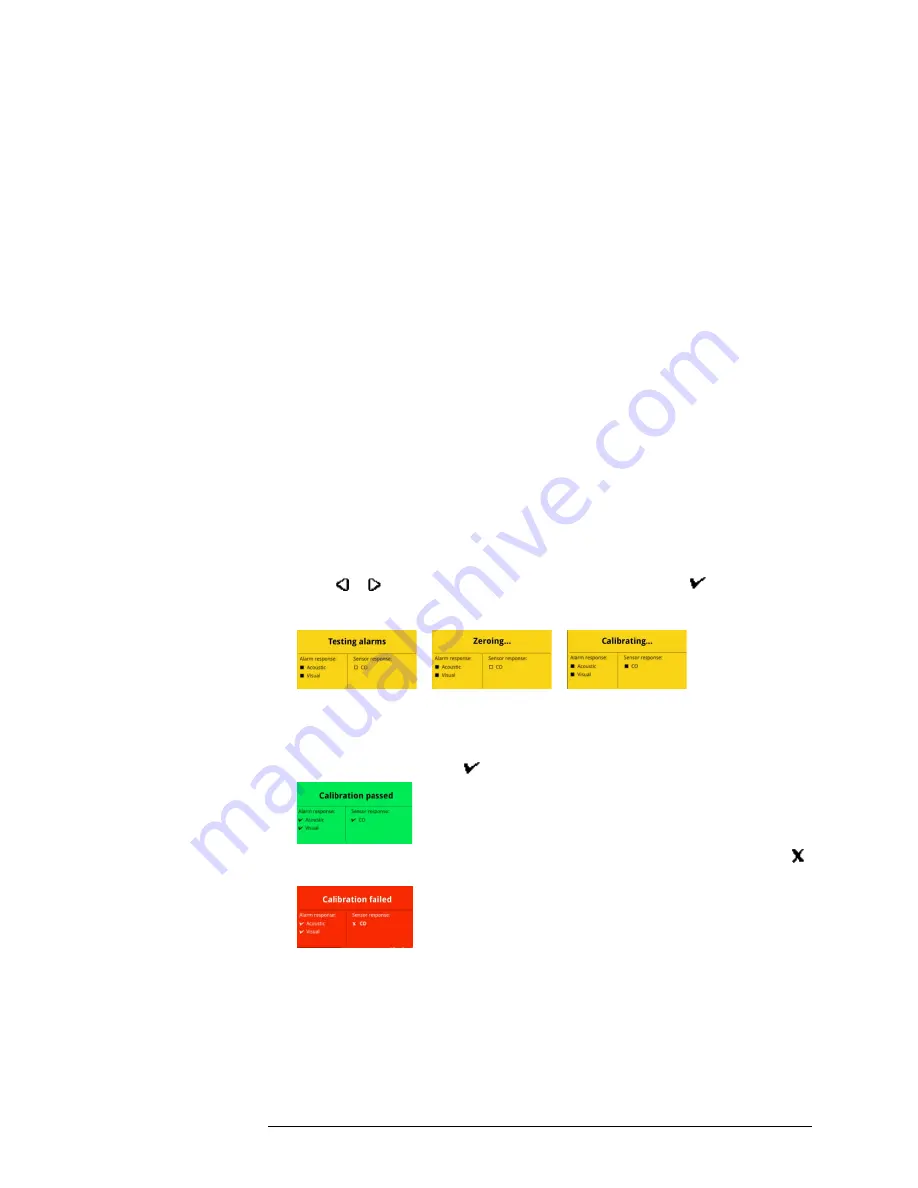

calibration starts automatically once the detector is recognized. Progress screens are

displayed while the tests are performed.

1. Insert a compatible detector into the module. The LCD changes to gray and

Detector

identification

is displayed.

2. When the module is configured to perform a calibration on overdue sensors and other

procedures on insertion and the calibration is overdue, the LCD changes to yellow

and Testing Alarms is displayed after the detector is recognized. Go to step 6.

3. When the module is configured to perform calibration and other procedures on

insertion and the calibration is NOT overdue, the other procedures are performed

after the detector is recognized. After the procedures are completed, What do you

need to do? is displayed on the LCD. Go to step 5.

4. When the module is NOT configured to perform calibration or other procedures on

insertion, detector operations menu and

What do you need to do?

are displayed

after the detector is recognized. Go to step 5.

5. Press or to scroll to

Calibrate my detector

, and then press . The

LCD changes to yellow and the calibration begins. Calibration begins. Progress

screens are displayed while the tests are performed.

6. If the module is configured via Safety Suite Device Configurator software to

automatically download datalogs, the detector datalogs are transferred to the module

after the calibration is complete.

7. When the calibration is successful, the LCD changes to green and

Calibration

passed

is displayed. Press to return to the detector operations menu.

8. If the calibration fails, the LCD changes to red and

Calibration failed

is displayed.

indicates failed alarm and/or sensor test.

9. To understand how to respond appropriately to failed tests, refer to the appropriate

detector operator manual.