(In this case, set auto function to “Manual” , set sensitivity to nearly center of bar

with Gain key and the depth to 20m with Range key. It is good when the bottom

is indicated in the strongest color (red).

(2)

Polish the surface of contact (bottom of transducer and inside hull) with sand paper

like No. 240 and drain all oil, water and stain with alcohol and etcetera.

(3)

Put the silicon bond on the surface of contact (bottom of transducer and inside

hull) and press the transducer firmly to the hull and gently twist to remove any air

bubbles and glue it.

(4)

Please check the display before resin is set. (same as above (1).)

If it is not displayed normally, it is considered glue is poor. Take off the transducer

inserting the knife or etcetera between transducer and hull plate and then glue it

correctly again. (Please take care not to hurt the transmitted side of transducer.)

(5)

Please fix the transducer for example, with weight not to slip contact until resin is

thickened. (It takes approx. 24 hours to thicken the silicon resin.)

×

Air is entered

×

Too thick

resin

×

If contact side

is uneven, resin

is too thick or

air is entered.

○

Good

×

No display

just only putting

glue around the

transducer

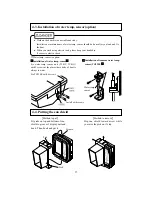

4-2-4. Installation in the fish reserve

(1) Drain the water from reserve.

(2) In case you glue the transducer on

the bottom of fish reserve, please

refer to “4.2.3. Inside hull installation”.

Fish reserve

Transducer

Lessen clearance as much as possible

Transom Bracket

(Standard Component

of TD03)

Single layer less

than 10mm

9

Note 1)

It is effective only for FRP or aluminum boat whose hull is single layer (less than

10mm).

Note 2)

Before gluing

,

put the transducer in fish reserve at the place where the depth is

enough and find the best location which gives you the best sensitivity.