10

ADH-Series | Version 1.05

Installation and erection

- The Planer-Thicknesser must only be installed and

operated in a dry, frost-free and well-ventilated

place.

- Avoid places nearby machines generating chips

or dust.

- Provide sufficient space for the staff preparing and

operating the machine and transporting the mate-

rial. Also consider that the machine is accessible

for setting and maintenance works.

- Provide for sufficient illumination (Minimum value:

300 lux)

- There must be a extraction device with min.

690 m

3

/h extraction capacity, min. 20 m/s flow rate

at the hood connection; Hose diameter 65 mm,

max. hose length 4 m.

7.2 Installation of the Planer-Thicknesser

The Planer-Thicknesser is shipped complete in one car-

ton and Is already largely assembled. After delivery only

a few parts have to be installed.

Step 1: After unpacking from the carton lift the machine

and put it at the desired place of use.

Installation on a workbench

The Planer-Thicknesser can be installed on a

workbench using bolts, lock washers and hex nuts (not

supplied).- The planer-thicknesser must be bolted to a

firm, level surface.

Make sure the planer-thicknesser doesn‘t rock and the

tables are level.

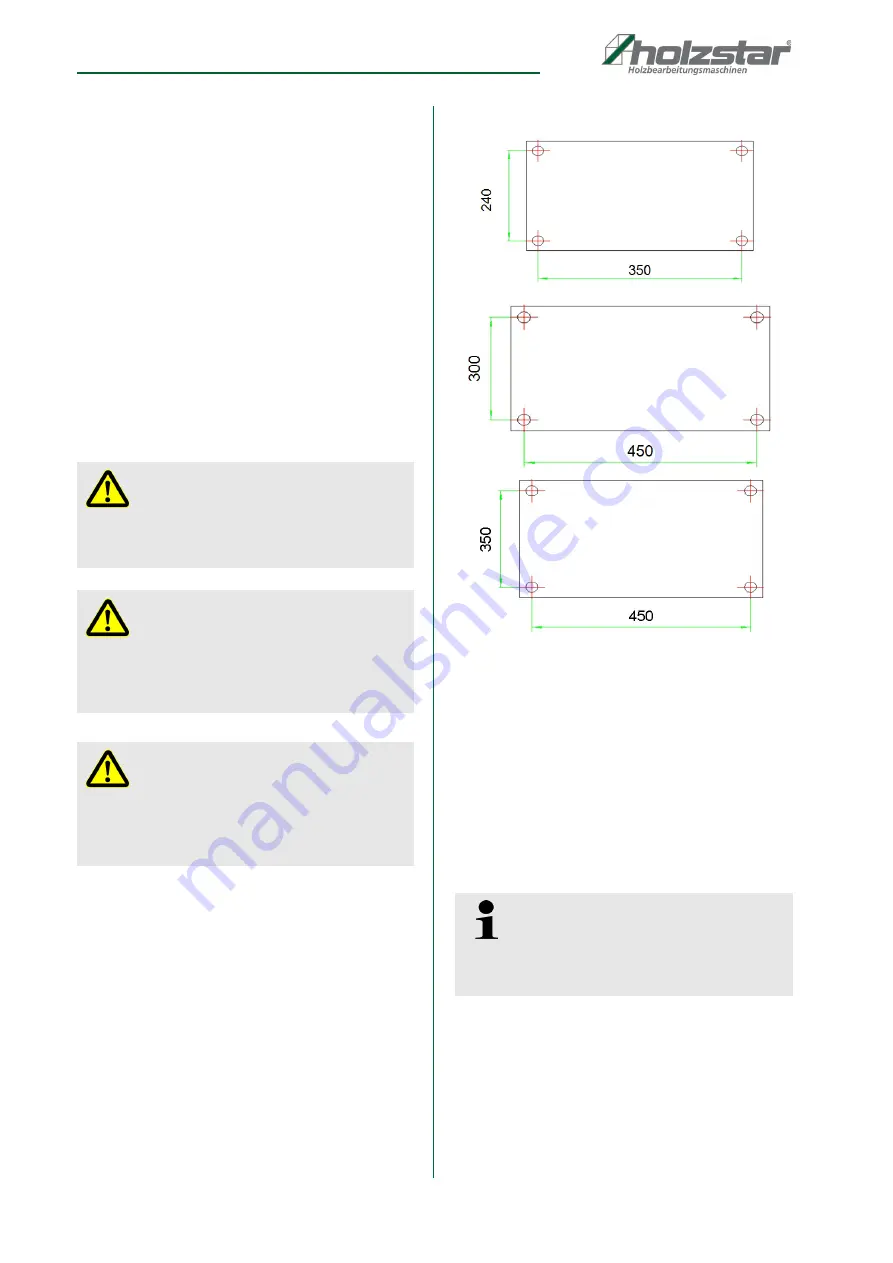

Fig. 5: Hole separation ADH 200 / ADH 250 / ADH 305

Mounting of the parts

Step 1: Attach the aluminium fence on the Planer-

Thicknesser with the 6 -1.0 x 16 mm screws.

Step 2: Assembly the Chip extraction hood with the two

brackets (depending on the operating mode)

and activate the safety switch.

Step 3: Connect the extraction hose and the dust bag.

Install of the extraction hose

Step1: Connect a extraction hose diameter 65 mm with

hose clamp on the ventilation hood connection of

the machine. Connect the other end of the ext-

raction hose with a hose clamp at intake socet of

the chip extraction hood.

ATTENTION!

Risk of injury through an unstable stand of the machine!

Check the stability of the machine after installation on a

stable backgroud.

ATTENTION!

Consider the weight of the machine!

The machine may be installed only by two persons.

Check the tools corresponding to sufficient dimen-

sioning and load carrying capacity.

ATTENTION!

To ensure sufficient stability of the machine, it should

be screwed to the ground. For this purpose, 4 drill

holes are located at the bottom of the machine hou-

sing

Tips and recommendations

The extraction device must ensure a extraction

capacity from min. 690 m

3

/h by flow rate min. 20 m/s

at the hood connection.

Summary of Contents for ADH 200

Page 1: ...Instruction manual ADH S ERIES Planer Thicknesser ADH 200 ADH 250 ADH 305 ADH 250 ADH 200 ...

Page 19: ...Spare parts ADH Series Version 1 05 19 Fig 18 Spare parts drawing ADH 250 ...

Page 20: ...20 ADH Series Version 1 05 Spare parts Fig 19 Spare parts drawing ADH 305 ...

Page 22: ...www holzstar de ...