❏ ❏

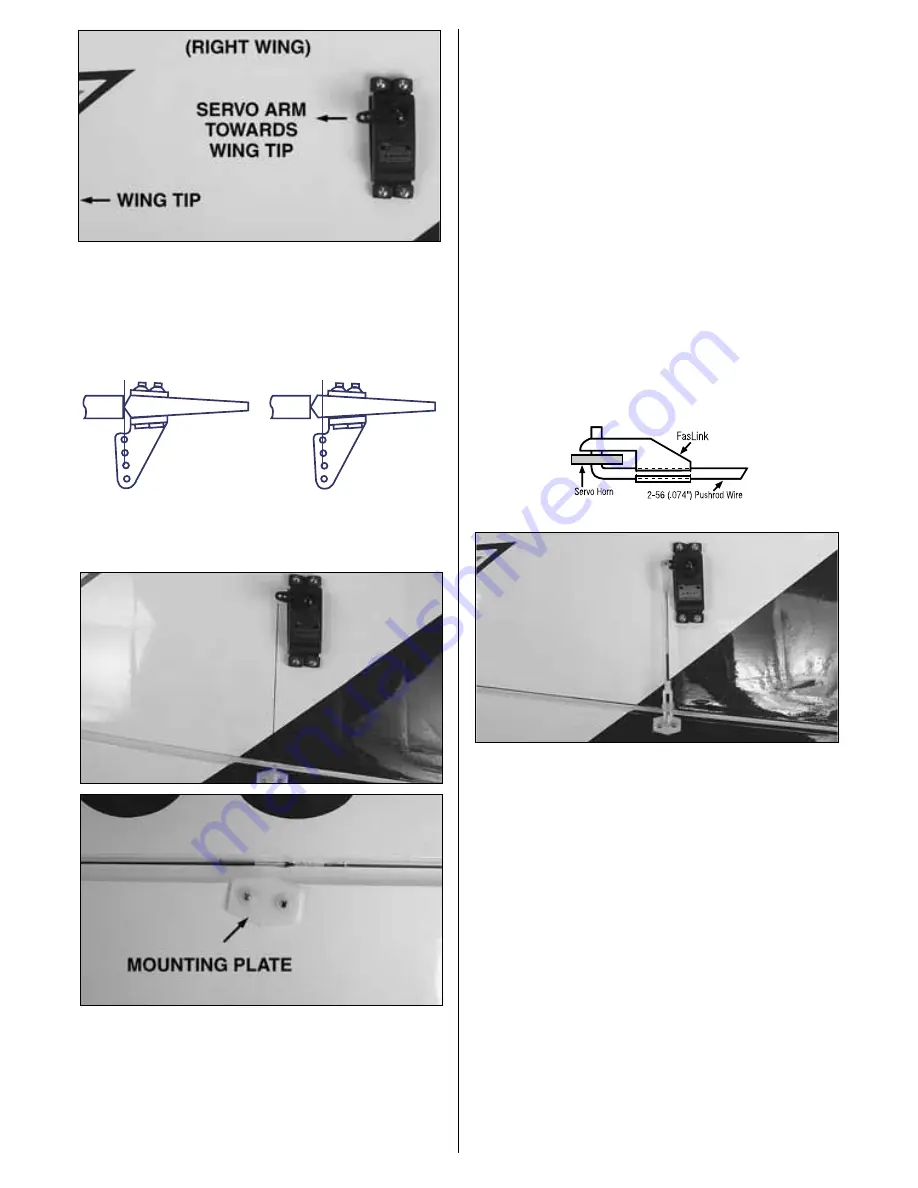

3. Install the servo into the wing. Center the

servo and install a servo arm as shown.

❏ ❏

4. Position a nylon control horn on the aileron as

shown in the sketch, aligning it with the servo. Mark the

location for the screw holes. Drill through the marks you

made with a 1/16” [1.6mm] drill bit, drilling through the

aileron. Secure the control horn to the aileron with two

2 x 20mm [3/4”] machine screws and the nylon

mounting plate.

❏ ❏

5. Locate a 2 x 102mm [4”] pushrod wire

threaded on one end. Screw a nylon clevis onto the

threaded end of the wire 20 full turns. Install a

silicone clevis keeper onto the clevis and then install

the clevis in the second hole from the end of the

aileron control horn.

❏ ❏

6. Be sure the aileron servo is centered.

Enlarge the second outermost hole in the servo arm

with a Hobbico Servo Horn Drill (or a #48 or 5/64”

[2mm] drill bit). Center the aileron and align the wire

pushrod with the hole in the end of the servo arm.

Using a marker, mark the location where the wire

aligns with the hole in the servo arm. On that mark

make a 90 degree bend. From the bend measure an

additional 3/16” [4.8mm], then cut off the excess

pushrod wire.

❏ ❏

7. Install the wire into the hole in the servo

arm using a nylon FasLink as shown in the sketch.

❏

8. Repeat steps I - 7 for the left wing panel.

Correct

Incorrect

8