the firewall to the front of the cowl is 5-3/8”

[136mm]. This dimension will properly space the

engine when using the spinner included with this kit.

If you are using a different spinner or no spinner you

may need to position the cowl further forward or

back to properly position the cowl. Place your

spinner and propeller on the engine to be sure you

have the proper spacing required.

❏

4. Double-check to be sure you have the proper

spacing for the cowl and that the cowl is centered on

the engine. Have your assistant hold the cowl while

you mark the location for the cowl mounting screws.

(The cowl mounting blocks are easily visible from

the back of the cowl.)

Begin on the right side of the fuselage first. Drill a 3/32”

[2.4mm] hole through the cowl and into the top cowl

mounting block. Install a 3mm cowl mounting screw

into the cowl. Double check the positioning of the

cowl and then drill the bottom hole. Repeat this for the

left side of the fuselage, checking the position of the

cowl after each screw is installed.

❏

5. Remove the cowl mounting screws and the cowl.

Put a couple of drops of thin CA into each of the screw

holes to harden the threads. Allow the glue to cure.

❏

6. Re-install the cowl onto the front of the

fuselage. On the cowl, mark the location for the

glow plug, needle valve, muffler or any part of the

engine that conflicts with the cowl. Using a rotary

tool, begin cutting small portions of the cowl,

making the holes progressively larger until the cut-

out matches your particular engine installation.

❏

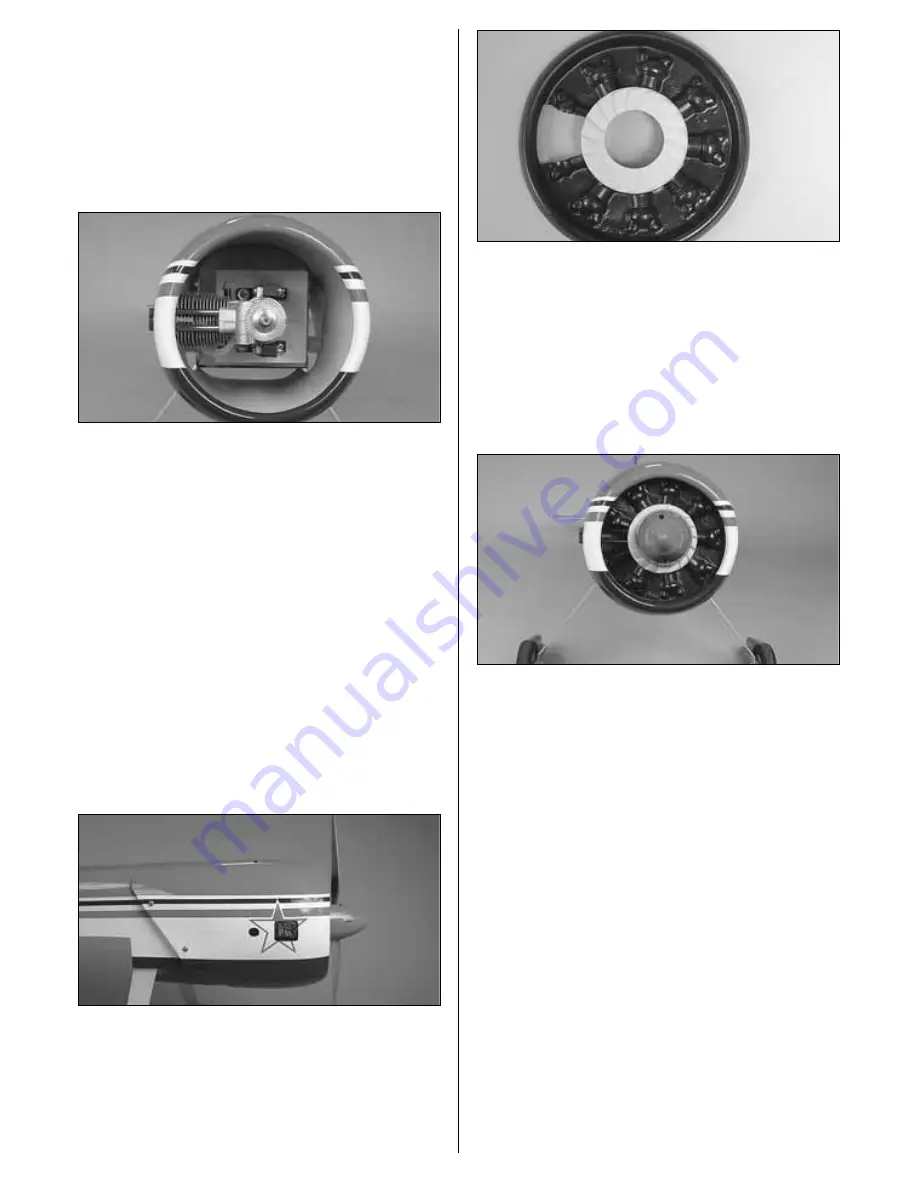

7. Cut the center of the plastic

dummy engine

to

fit around the front of the engine. Leave plenty of

clearance between the dummy engine and the

engine thrust washer. The spinner will cover any gaps

between the two. Mark the location of the engine

cylinder and then cut away this area from the

dummy engine. Paint the dummy engine with a fuel

proof paint. We painted the louvers a light gray and

the engine flat black.

❏

8. Slip the dummy engine into the cowl and then

install the cowl onto the fuselage. Position the

dummy engine, centering it with the engine. Using

medium CA glue with a micro-tip on the bottle, tack

glue the dummy engine to the cowl. Once the

dummy engine is secure to the cowl, remove the

cowl and permanently glue the dummy engine in

place by applying a bead of glue to the back of the

dummy engine from inside the cowl.

16