– 3 –

PL-41408-1

SHARPENER

DEFLECTOR

TOP KNIFE COVER

CARRIAGE TRAY

CARRIAGE TRAY /

SUPPORT ARM

FENCE

INSTALLATION

UNPACKING

Immediately after unpacking the slicer, check for possible shipping damage. If the slicer is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installing the slicer, test the electrical service to assure it agrees with the specifications on the

machine data plate. The data plate is located on the right side of the slicer base.

CARRIAGE TRAY

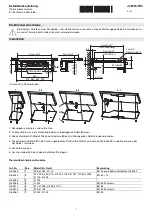

The Carriage Tray is secured to the slicer when the knob on the Carriage Tray / Support Arm is turned

clockwise until snug (Fig. 1). Refer to page 7 for assembly information.

SHARPENER

The Sharpener should already be mounted on top of the slicer and locked to its bracket (Fig. 1).

TOP KNIFE COVER

The Top Knife Cover should already be in place and secured with its Latch Knob (Fig. 1).

DEFLECTOR

The Deflector should already be mounted below the knife (Fig. 1).

FENCE

(Low and High Fences are used with front-mounted meat grip only.)

Either Fence (Fig. 1) can be clamped on the Carriage Tray to limit product movement during slicing.

Model 2812

Fig. 1

ELECTRICAL

WARNING

:

THIS MACHINE IS PROVIDED WITH A THREE-PRONG GROUNDING PLUG. THE

OUTLET TO WHICH THIS PLUG IS CONNECTED MUST BE PROPERLY GROUNDED. IF THE

RECEPTACLE IS NOT THE PROPER GROUNDING TYPE, CONTACT AN ELECTRICIAN.

CLEAN BEFORE USING

The 2812 or 2912 slicer must be thoroughly cleaned and sanitized after installation and before being

used. Refer to Cleaning, page 6.

1. Back out Thumb Screw.

Lay Fence on Carriage Tray.

2. Rotate to Vertical.

3.

Slide Fence Up. Tighten Screw.