-21-

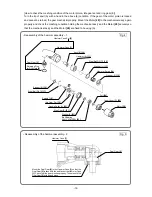

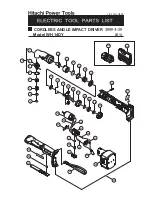

• Mounting the guide sleeve

Fig. 10

Push down

J-295 jig (B) for

retaining ring

J-295 jig (A) for

retaining ring

Retaining Ring

[9]

Washer (D)

[8]

5. Mounting the guide sleeve

(1) Insert two Steel Balls D3.5

[3]

into the hole of

anvil (A) of the Final Gear

[2]

. Mount Guide

Sleeve (D)

[6]

, Guide Spring (C)

[7]

and

Washer (D)

[8]

in sequence. Mount the

Retaining Ring

[9]

into the groove of the anvil

using J-295 jigs (A) and (B) for retaining ring.

NOTE:

Be sure to replace the Retaining Ring [9]

with new one because the Retaining Ring [9]

may be deformed and Guide Sleeve (D) [6]

may come off if the deformed Retaining Ring

[9] is used again

.

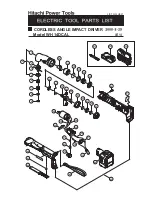

ALBANIA RL3

• Pinion tooth flanks of the Motor

[28]

, tooth flanks of Ring Gear (E)

[21]

and Idle Gear Set (2 pcs.)

[19]

,

gear tooth flanks of the Hammer Case

[1]

and the Final Gear

[2]

• Two Steel Balls D3.5

[3]

• Sliding section between anvil (A) of the Final Gear

[2]

and Guide Sleeve (D)

[6]

MOLUB-ALLOY 777-1

• 6 mm diameter hole of Anvil (B)

[10]

and the involute spline

• Two Steel Balls D4.76

[17]

• Cam groove, oil groove and claw of Hammer (A)

[11]

• Cam groove and sliding section of the Spindle

[18]

• 3.5 mm diameter hole of the Idle Gear Set (2 pcs.)

[19]

• All around Needle Roller (A)

[20]

• Twenty-four Steel Balls D3.175

[12]

• Second pinion involute splines of the Hammer Case

[1]

and the Hammer Case Set

[5]

• Oil groove of anvil (A) of the Final Gear

[2]

and sliding section of metal (A) of the Hammer Case

[1]

• Oil grooves of the Hammer Case

[1]

and the Hammer Case Set

[5]

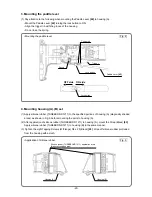

• Tapping Screw (W/Flange) D4 x 20 (Black)

[26]

------------------------- 1.96±0.49 N

•

m {20±5 kgf

•

cm}

Application of lubricant

Tightening torque