-11-

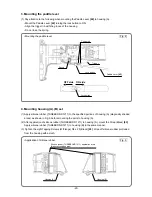

2. Tightening torque inspection prior to operation

As described and shown in page 7, the output tightening torque of the Models WH 14DCAL and WH 14DY

may exceed the rated tightening torque of certain bolts and screws. Accordingly, if the tightening time is

prolonged for such bolts and screws, the screws or the bolts may be damaged or sheared off. (This

phenomenon is common to all existing impact drivers.)

Particularly when tightening M6 (1/4") or smaller screws, tightening time must be kept extremely short: 0.5

seconds or less. The customer should be advised to carry out several screw tightening operations and

adjust the tightening time as necessary by measuring the tightening torque with an appropriate torque

wrench or driver before commencing continuous operation.

3. Tightening torque variation

The tightening torque of the cordless impact drivers or wrenches may vary slightly in accordance with the

factors described below. Salespersons are requested to advise the customers to confirm that the

appropriate tightening torque is obtained by measuring the torque with an appropriate torque wrench or

torque driver at the beginning of the tightening operations, and as necessary during the tightening

operations. In addition, the torque values shown in page 6 above are useful as a handy reference, and may

be utilized as tentative standards.

(1) Voltage of battery

The tightening torque is affected by the voltage output of the battery. The tightening torque decreases

as the number of bolts tightened increases. This phenomenon is caused by the decline in voltage output

of the battery due to the increasing number of bolts tightened. In particular, the tightening torque

decreases rapidly just before the overdischarge protection circuit is activated. As this phenomenon is an

inherent drawback in any cordless impact driver/wrench, salespersons are requested to ensure that the

customers are fully aware of and understand this characteristic.

Precautions for use of the Type BCL 1430 lithium-ion battery

The Type BCL 1430 lithium-ion battery is equipped with a protective function that automatically stops

output to extend the battery life. The motor may stop automatically even though the switch is depressed

continuously when the remaining battery level is low (about 8 V or lower). This is because the protective

function is activated and the battery is not faulty. Charge the battery immediately in such case.

(2) Effects of low ambient temperature

The tightening torque required may be reduced at low ambient temperature under the influence of

grease and different torque coefficients (depending on manufacturing and finishing processes, and

specified by bolt manufacturers).

(3) Different bolt diameter

Difference in bolt diameter may cause variation of the required levels of tightening torque. Generally,

high tightening torque is required for large bolts.

(4) Different materials tightened

When a bolt is tightened into a soft material such as aluminum, plastic, wood, etc., the tightening torque

is considerably low in comparison with the tightening torgue reguired for tightening a bolt into a hard

material such as steel.