--- 16 ---

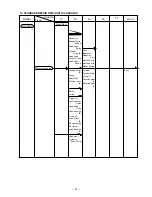

Plunger (A), valve piston (B),

valve bushing (A) or valve

bushing (B) is abnormal

(galled or damaged).

O-ring is worn or oiling is

needed.

Air pressure is too low.

Piston O-ring is worn or

damaged.

Piston bumper is abnormal

(dislocated, deformed or

damaged).

O-ring of the cylinder is

abnormal (dislocated,

deformed or damaged).

Driver blade is abnormal

(deformed, burrs, damaged

or fatigued).

Cylinder's internal surface is

abnormal (deposits of dirt or

worn).

Head valve sliding surface is

abnormal (galled, damaged

or needs oil).

Head valve spring is

abnormal (fatigued or

damaged).

Problem

Possible cause

Inspection method

Remedy

Pull the nail feeder

backward and perform idle

driving. Check if the driver

blade has returned.

Check if nails can be driven

at 5 kgf/cm

2

.

While operating the nailer

without nails, check if the

drivng operation is

performed.

After operating the nailer

without nails, check if the

driver blade is kept in the

down position.

After making idle driving,

check if the driver blade is

kept in the down position.

Disassemble the control

valve and check the O-ring.

Adjust for 5 to 8.5 kgf/cm

2

.

Replace the piston ring.

Replace the piston bumper.

Reassemble or replace.

Repair or replace.

Remove the dirt and apply

oil, or replace.

Replace the defective part.

Apply grease.

Replace the head valve

spring.

Replace the defective part.

Apply grease, or replace.

<

Output section>

<

Control valve section>

Summary of Contents for NR 90AC3

Page 39: ......